Modular sets of brewery tanks means freedom of making decisions and new opportunities.

The best choices are those that can be changed anytime

Jan Šablatura, Sales Manager, Czech Brewery System s.r.o

A Czech manufacturer, of brewery sets equipment, decided to solve the worries of industrialists at breweries and brewers for their own requirements. Inspired by the necessities of his customers, mostly in North and West Europe, which in turn led to the creation of brewery tanks with modular construction. The rest as they say is history, creation of Czech Brewery System s.r.o.

A MODULAR SET: CCTM SYSTEMS

Do you plan to build a minibrewery and not sure which brewery tanks to buy for production? Or looking to increase the production capacity of your brewery? Then the CCTM modular system of brewery beer production tanks could be a good solution for you because the best solutions are the ones which you can change easily, the main theme of the Cylindrical-Conical tanks designed as a modular set. Modular sets of brewery tanks means freedom of making decisions and new opportunities.

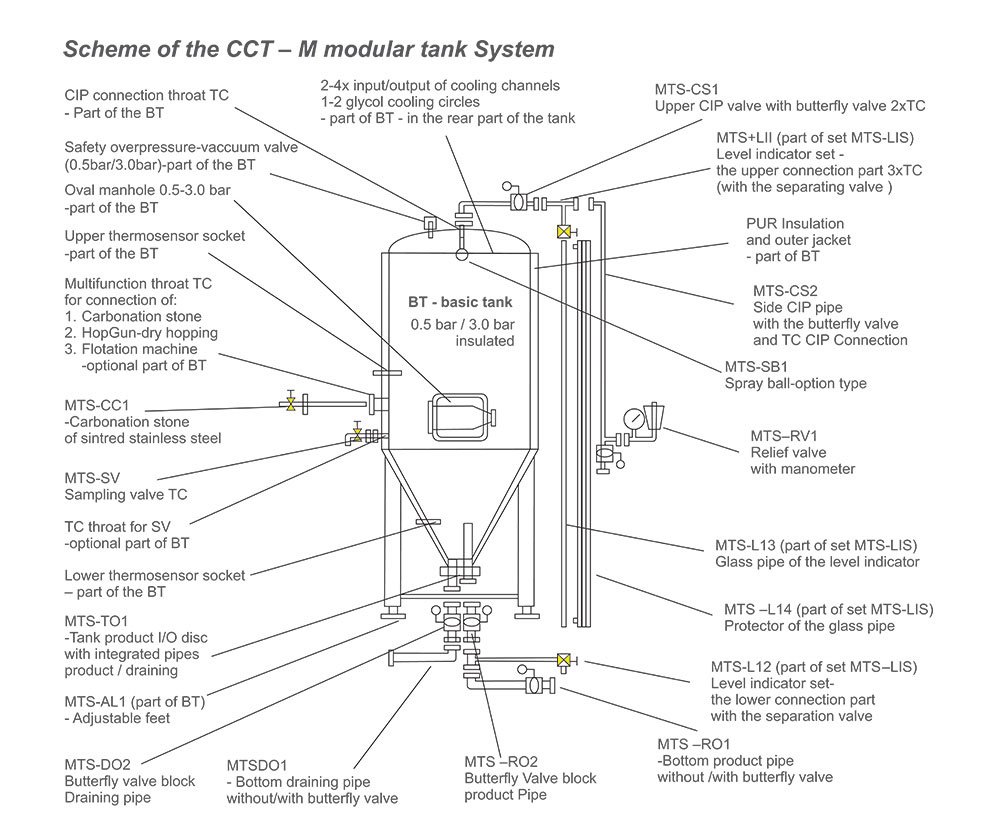

The main component of the CCTM system is a basic tank. It is a pressure vessel with many added armatures to which different extendings, equipment and accessories can be added as per the breweries reqiurements. The basic tank is manufactured in two variations according to maximal allowed overpressure, in combination with three levels of quality surface of internal and external stainless steel plates – standard quality, high quality and top quality. This enables the buyer to choose the quality and variations of tanks that will suit his requirement and budget.

In the diagram above, you will see a detailed image of the basic tanks and its components.

- Inspection Manhole (IM) a 450×350 mm with an arm at the cylindrical part of tank. At a maximal pressure 0.5 bars or 0.3 bars

- Safety Valve (SV) for protection of tanks against overpressure (0.5 or 0.3 bars) and underpressure (0.2 bars)

- Sanitizing Port (CP) TriClamp DN25 for connecting a sanitation pipe

- Adjustable Legs (AL) for tanks with a volume of upto 3000 liters there are three legs. The bigger tanks have four legs, screwing legs for exact positioning and levelling tanks

- Bottom Throat (BT) for connecting conjugate armature for saturation and draining tanks

- Cooling Throats (CT) Threaded pipes for connecting ice cooling water tanks or glykol blend

- Cooling Channels (CC) Channels embracing the cylindrical areas and conical areas for circulation of cooling water or glycol for cooling tanks, eventually used for heating

- Thermometer Sockets (TS) for sensing head instalations, which measure a temperature for water regulation in tanks

- Handling Eyes (HE) for manipulation with tank with help of suspension technology

- Ladder Consoles (LC) for better access to the higher areas of the tank

- Fixing Concoles (FC) meant for gripping of the sanitizing pipe and level meter with screwing stirrups

- Sample Valve (SV) for connection of strobe valve

- Multifunction Throat (MT) TriClamp for connecting extended armatures – filling plugs for filling of beverages, HopGun for cold hopping, floatation tool for decantation of beverages

EXTENDING ACCESSORIES

The extending tank equipment makes a modular cylindrical-conical tank interesting compared to other tanks with regular concept. Manufacturer offers the modular tanks in 5 recommended different variations, this should help a customer to make a consisdered decision. But it is upto the customer to decide with which equimpent he will support the tanks, and what is important the configuration of CCTM tanks which he can change anytime.

Recess the tanks with extending armatures is really easy because all units are connected with a TriClamp connection, it is patented system of pipes connection. This patented system was developed specially for food equipment. Its main advantage is easy assembling and disassembling, and its possibility of sanitation. So the whole set can be easily washed with water and with sanitation fusions either in disjoined estate or in joined estate without requirement of disassembling of tanks.

ADVANTAGES OF THE CCT-M MODULAR TANKS

- Easy sanitation of de-sludge pipes and level gauge, even when the tank is full of beer

- All equipment in the tank is removable and changable. So, you can use the armatures on the body of the tank for different equipment and change the usage of the tank. For example, you can use it one week for fermentation and another week for dry hoping or tapping. You can even change the tank so that it can be used for production of cider. Changing of equipment in regular model tanks is a problem because of the pressure certification, again. Czech Brewery tanks are ready for changes without losing the certification

- You can share select equipment among several tanks, which saves costs. For example, you can buy one level gauge for several tanks. You can remove the gauge from one tank and attach it to another, when you need to find actual level of beer in the tank. This can be done even when the tank is full of beer

- Easy maintenance. If something is broken, it can be removed and replaced easily

- Easy for manipulation and transportation. Our tanks are simple body design, equipment has no risk of damage during transport and manipulation

The company’s design and production team offers construction and modernization of breweries and microbreweries. The breweries and brewing equipment manufactured by Czech brewery system are installed in Russia, Sweden, Netherlands, Norway, Ireland, Great Britain, Finland, France, Belgium, Switzerland, Poland, Malaysia, Korea, Japan and in many other countries.