Beer Recovery from Surplus Yeast in Breweries

Sanjay Sapru

Executive VP & BU Head

Brewery Business, PRAJ Industries

Recovering beer from surplus yeast in brewery plants provides an attractive opportunity for improving beer productivity. A valuable approch for improving overall production efficiency is to recover beer from surplus yeast. Praj – Bucher Unipektin Cross-flow filtration technic using ceramic membranes serves the purpose of recovering beer from surplus yeast.

Charecteristics:

The system is equipped with a compact cross-flow filtration plant with ceramic tubular membranes. The system consists of two main parts, the filter unit and the CIP station. Both parts can be arranged separately or on a common skid. Different automation levels are available, from manually controlled units up to fully automated plants.

The special design of the so-called dual-flow modules allows high packing density of filter surface, which leads to small footprints and lower heights of the plant. Especially because of the latter, it is easy to maintain. Due to the compactness of the plant, its inner volume is small compared to the installed filter area. This leads to low water and energy consumption as well as low product losses. Tailor-made ceramic membranes for beer recovery from surplus yeast guarantee high economical benefit and high quality of recovered beer. The high durability of the membranes, together with a well proven process, lead to very reliable systems with very low demand for operator presence and maintenance. This, and the short pay back periods, make this technology as a standard solution for beer recovery today.

Basic Process:

During the brewing of beer, surplus yeast settles in the fer mentation and storage tanks. The total volume of surplus yeast represents about 2 to 3% of a brewery‘s output. Approximately 50% of the volume of surplus yeast is beer, which is lost to the brewery if the slurry is sent untreated to farms or food producers. If yeast is discharged into the sewage system, very high treatment charges arise because of the very high biological oxygen demand. The average B.O.D. value is around 140,000 mg/kg. For these reasons, the valuable component “beer” is recovered from surplus yeast.

Working Principle:

The cross-flow principle as shown in the following picture is characterised by the flow directions of the unfiltered and filtered liquid, which are perpendicular to each other.

The cross-flow principle as shown in the following picture is characterised by the flow directions of the unfiltered and filtered liquid, which are perpendicular to each other.

The preferably turbulent flow of the unfiltered liquid, which is parallel to the membrane’s surface, prevents particles from depositing on the membrane or carries away already deposited substances. Hence the throughput of filtered liquid through the membrane is kept high.

A pressure gradient across the membrane forces the filtered liquid to penetrate the membrane.

Charecteristics of Membranes:

For the beer recovery, process tailor made ceramic membranes in tubular multi channel elements are available.

The robustness of the ceramic material guarantees long life time of the membranes, high availability of the plants, low membrane replacement costs and low maintenance costs.

| Channel diameter | 8 mm |

| Pore size | 0.3 µm |

| Pressure resistance | 30 bar |

| Temperature | > 90° C |

| pH | 0~14 |

Quality of Recovered Beer:

The membrane’s pore size of 0.3 μm guarantees high quality of recovered beer:

| Turbidity of filtrate | < 08. EBC ( 90° angle ) |

| Yeast cells in filtrate | < 5 cells / 100 ml |

| Bacteria reduction | > 105 |

The Dual-Flow Module:

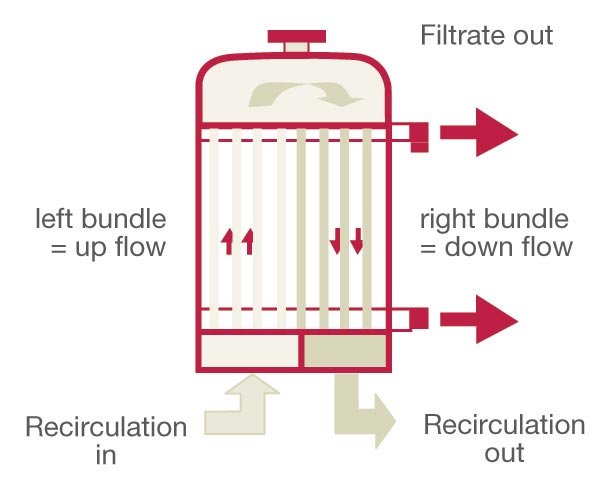

The name of the dual-flow module is derived from the two different flow directions upwards and downwards of the unfiltered liquid in the channels of the installed ceramic elements.

The name of the dual-flow module is derived from the two different flow directions upwards and downwards of the unfiltered liquid in the channels of the installed ceramic elements.

Thanks to this concept, a maximum of packing density and a minimum of pipe connections are achieved. Complete venting and draining is guaranteed by discharging the liquid through the top and bottom plate.

This concept allows for easy maintenance by simply taking away the top cover of the housing.

With two different sizes of dual-flow modules, one with 20m2 filter area, the other one with 48m2, and hence by modularly increasing filter area, an optimal plant design for all required brewery sizes is possible.

Space Requirements:

The maximum height of these plants amounts to 3.3 metres. The required floor space for the CIP station is around 2.5 x 1.0 m. The required floor space depends on the number and type of dual-flow modules installed. Some typical values for plants with the bigger type of module are:

| No. of modules | 1 | 2 | 3 |

| Filter area / m2 | 48 | 96 | 144 |

| * Yeast / hl / day | 240 | 480 | 720 |

| Space / m | 2.2×2.0 | 3.0×2.0 | 3.0×3.0 |

*depending on dry matter and gravity; incl. diafiltration

Process:

Beer recovery works according to the “batch principle”. While the yeast is recirculated through the plant and the batch (feed) tank, beer is recovered.

The concentration of the yeast increases slowly so that the plant works only for a very short period with the maximum concentration.

The specific flow rate is increased by this type of process. A semi-continuous operation can be achieved by substituting the volume of the recovered beer by fresh feed yeast slurry until the tank is filled with highly concentrated yeast. Diafiltration can be applied for increasing extract yield and, hence, increasing the economical benefit. For these purposes, recovered beer is substituted by deaerated water. The remaining beer in the yeast slurry is continuously diluted so that beer with slowly decreasing gravity is recovered.

Typical ROI Calculations

| Basics | |

| Plant Capacity | 1.0 million hl/annum |

| Surplus Yeast Quantity (approx.) | 35,000 (Max) hl/annum |

| Average Yield (approx.) | 71% |

| Recovered Beer Per Year (HGB) | 24,850 hl/annum |

| Approximate cost of Beer Recovery System | 4,50,00,000 INR |

| Depreciation & Interest (5 years amortization & 12% rate of interest) |

1,24,83,438 INR/annum |

| Variable / Operating Cost | 15,53,125 INR/annum |

| Membrane Replacement Cost | 10,05,900 INR/annum |

| Total Cost Including Capital Cost | 1,50,42,463 INR/annum |

| Additional Benefits due to lower load on ETP | 21,00,000 INR/annum |

ROI |

2.5 Years |

About PRAJ Industries:

What started off as an entrepreneurial venture three decades ago, is today India’s most successful company in the field of bio-based technologies and engineering with presence all over the world. The zeal of working toward making the world a better place has stayed with us till today and will continue to do so. With a humble beginning as a supplier of ethanol plants, today Praj is a globally leading company with a bouquet of sustainable solutions for bioenergy, high purity water, critical process equipment, breweries and industrial wastewater treatment. Headquartered in Pune, India, Praj has spread its presence across the globe with more than 750 references in more than 75 countries.

Praj supplies world class brewery plants capable of producing the best quality beers at the most optimum costs. Right from conceptualization, technology, design, plant engineering up to project installation and commissioning. Praj offers complete solution backed by expertise and experience. Breweries supplied by Praj are environment friendly utilizing minimum water, energy and with low carbon footprints.