The Ideal Tools for Craft Brewers

HANAGUDU, HARISH

Krones India Private Limited

DR. RALPH SCHNEID

Krones AG Steinecker plant

To translate their flavour ideas into marketable reality, craft brewers need a reliable tool if they are to produce creative beers at a consistently high level of quality. Krones’ portfolio accordingly includes various products designed specifically for craft brewers.

MicroCube–modern-day technology for small brew sizes

The MicroCube brewing system is for a brew size of five or ten hectolitres, which is featuring a brewhouse and a fermentation cellar. The concept also includes the water, heat and refrigeration supply. The pre-assembled modules are installed and commissioned within a minimised timeframe and have compact dimensions. The vessels diameters measure not more than 1,200 millimetres, while the valve and pump module measures 1,000 x 1,000 x 2,150 millimetres. The entire scope of delivery can be accommodated in three to four 40-foot containers.

The MicroCube’s electronically aided, manual operator control concept is extremely flexible and easy to handle. For the milling operation, a two-roller grist mill is provided with a milling capacity of 500 kilograms per hour with manual malt feed and grist removal. The mash-lauter tun is fitted with a wall heater for the mashing process. For lautering, it utilises the field-proven false-floor design employed in large-tank construction. A pitot tube enables the lautering function to be manually regulated.

The whirlpool is fitted with wall and floor heating to ensure optimal heat-up rates. A Stromboli riser, additionally, intensifies the evaporation of base aromatics. There is an option for integrating a simple vapour precipitation capability featuring spray heads in the vapour pipe or a vapour condenser for producing warm water. The warm water is stored in a water tank with wall heating, temperature display and a “full” signal. The high-speed steam generator supplied with the system produces 50 kilograms of saturated steam per hour. The refrigeration is supplied by a compact cooling system: it chills glycol, which is stored in the glycol tank, for cooling the tank(s) and the wort. For the brew size of five hectolitres, a cooling capacity of twelve kilowatts is installed; for ten hectolitres the figure is about 17 kilowatts. As the CIP system, a one or two-tank version is available. The standard process is non-circulatory CIP cleaning with a buffer tank.

For fermentation tanks, there is a choice of tanks featuring 5, 10, 20, 25 or 50 hectolitres net capacity with wall and cone heating.

The Krones Craftmate–compact and versatile

Krones also has a can filler for the low output range in its portfolio: the Craftmate. This modularised, volumetric filler, with its 24 filling valves, has a pitch circle diameter of 1,080 millimetres. It is suitable for both small firms and craft breweries. The Craftmate has been developed as an autonomous machine. The filler has in some points been deliberately designed for a simpler construction than the can fillers produced by Krones hitherto, and has extremely compact dimensions. During cleaning, for example, the CIP cups are inserted by hand and an automatic external foam-cleaning feature or hot-water gush-type jetting can be integrated as options.

Thanks to its innovative technology, the Craftmate can be operated without a lifting cam. This saves on components and makes the machine more easily accessible. The filler is in open design and thus simple to clean as well. The cleaning media run down the sloping table-top into a defined drain and thus cannot collect in puddles. From the table-top, the filler is very conveniently accessible for maintenance purposes. For maintenance work on the distributor, this can be removed upwards.

The electrical control cabinet is connected directly, with concomitant space savings. The pneumatic control system for the valve rack is also integrated here. The compactly dimensioned valve rack is located directly behind the filler together with the product tank, and the adjacent seamer is electronically block-synchronised using servo-technology.During the development stage, priority was intentionally given to high flexibility for the different products and container formats concerned. The Craftmate has been designed for filling cans in the standard 211/202 format, but can optionally also be set up for the 204/202 to 300/209 formats. The machine’s output depends on the can volume and the product parameters involved.

CombiCube–think big, act flexible and produce small

Learn from “big” brewing technology and use it for producing specialty beers in small batches: a balancing act that Krones AG has mastered with the CombiCube system. The CombiCube is predesigned for relatively small specialty breweries, producing up to 250,000 hectolitres of sales-quality beer that handle highly diversified product ranges and seasonal products. The system is modularised in construction, permits individualised system design, and is easily expandable. The nature and number of the vessels can be put together to suit the requirements involved. The CombiCube gives breweries an option for producing high-quality products with different brewing processes and high volume variance.

Three components for brewhouse, filtration and cellar

The three “cubes” are the CombiCube B Brewhouse, the CombiCube C Cellar Unit, and the CombiCube F Filter. Role models from the large equipment category, like ShakesBeer, the Twin Flow System or TwinPro have been used, retaining their functionality, reducing the amount of equipment involved, and exploiting the advantages of their “small” size. Thus operator-friendly, field-proven technology is made accessible to small and mid-tier breweries as well.

The compactly dimensioned brewhouse covers an output range of 40 to 100 hectolitres of hot cast wort with up to ten brews a day and original gravities of up to 15 degrees Plato at 98.5 per cent extract yield. It can be combined with the mash tun, wort copper/cereal cooker, lauter tun/mash-lauter tun, wort copper/mash-wort copper and whirlpool vessels.

The compactly dimensioned brewhouse covers an output range of 40 to 100 hectolitres of hot cast wort with up to ten brews a day and original gravities of up to 15 degrees Plato at 98.5 per cent extract yield. It can be combined with the mash tun, wort copper/cereal cooker, lauter tun/mash-lauter tun, wort copper/mash-wort copper and whirlpool vessels.

CombiCube C–performing manual work automatically

The CombiCube C is precisely the right choice for breweries that operate a traditional fermentation cellar with hose connections for the tanks, but nonetheless want to benefit from the advantages of a process control system and are therefore planning to modernise their cold zone. The newly developed concept combines the freedoms of a hose-type cellar with a perfect overview of the functions ongoing in the entire fermentation cellar.

It offers an output range for filling and draining of up to 110 hectolitres per hour, a yeast harvesting output of six hectolitres per hour, and is thus adequately dimensioned for the CombiCube series or for breweries with up to 250,000 hectolitres of sales-quality beer. The CombiCube C handles the “Fill fermentation tank”, “Transfer young beer” “Yeast harvest”, “Transfer to filtration”, “Fill bright-beer tank” and “Transfer to filler” functions.

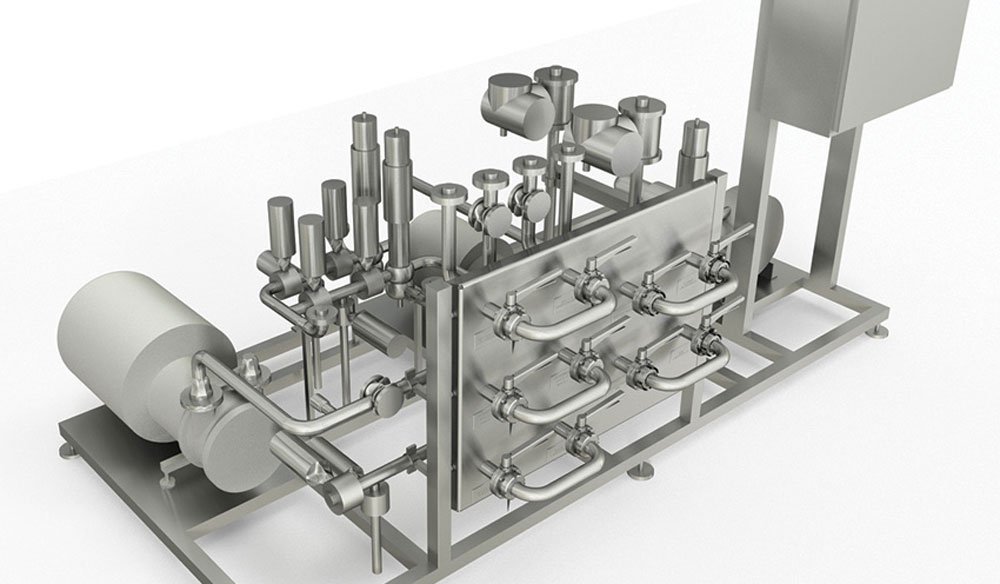

CombiCube F–modularised filtration

Five functionally defined modules are optimally harmonised in the CombiCube F, and can be combined with each other on the modular principle: the filtration module, buffer module, carbonation module, disposal module and the CIP module. The modularised design means that subsequent expansions are easy to implement. The wide adjustment options for the filtration output, made possible by the twin-flow principle, offer simple solutions for complex job profiles. The CombiCube F operates in a nominal output range of 26 to 104 hectolitres per hour with continuous running times of up to 14 hours. It is available in six different sizes.