Siemens Launches The New And Improved BRAUMAT In India, With Smart Financing Options

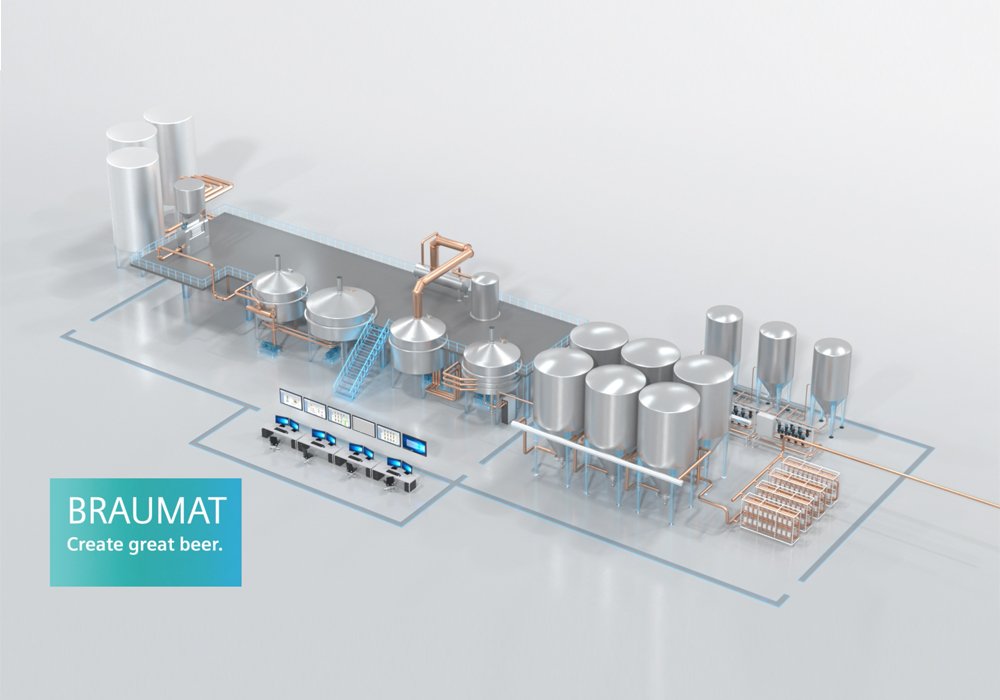

BRAUMAT V8: The Innovative Process Control System for the Brewing and Beverage Industries. It is efficient, flexible – and a safe investment for the long term.

Alongside hops, malt, yeast and water, a fifth kind of raw material is becoming more and more important for breweries: process data – from incoming raw materials to outgoing finished goods. Process data provides the basis for optimizing operations, saving energy and increasing output when capacities are low or need to be maintained at constant levels.

To meet these challenges, specific process automation systems are a must. BRAUMAT V8, the state-of-the-art process control system from Siemens builds on more than 45 years of experience to provide solutions to these demands. More than 500 breweries worldwide have been using Siemens’ BRAUMAT solution to produce beer in a safe and reliable manner, while maintaining a consistently high product quality.

The latest version of BRAUMAT 8.0 is based on the Simatic S7-1500 controller and has been optimized in the areas of reporting, weighing systems and security. With the Lean Edition the BRAUMAT system is the perfect fit for craft breweries with the option to grow and expand the system step by step.

In order to enhance the reporting possibilities, a batch report with a basic choice of process parameters has also been integrated. Users can now create reports with the help of MS Excel. BRAUMAT V8.0 is also now connected to the established PM-Quality reporting Addon. This means that MES (Manufacturing Execution System) and MIS (Management Information System) functions are supported with the MES API and SQL-Adapter which fits perfectly with the Siemens Opcenter Execution.

In the new version, storage location management is integrated together with dosage management in the recipe system, enabling the efficient and flexible automation of mixing processes. Recipes are automatically adjusted according to storage location availability and the quantity specifications of batches to be produced. High-precision, self-optimizing weighing operations are fully automated with the integrated Siwarex FTA or Siwarex WP351 weighing system.

The BRAUMAT V8.0 process control system continuously checks recipes and quantities for the individual production processes, thus reducing overdoses of malt, hops and diatomaceous earth. A combination of password protected Simatic S7-1500 controllers, encrypted communication on the terminal bus as well as extended user management and company ID registration via an RFID card reader increases security during the production sequences.

With this new version, BRAUMAT is safer and more flexible and efficient. That’s helped in part at the control level by the SIMATIC S7-1500, which is now fully supported in addition to the SIMATIC S7-400. So you benefit from efficient engineering in the TIA Portal and many new process control functions that fully support the brewing process – including combined operation with the SIMATIC S7-400. Safe, quick, flexible – and a safe investment for the long term.

Siemens Financial Services enables breweries in implementing technology with our customized financing solutions. You get all the benefits of enhanced recipe-control and higher flexibility immediately, while paying for the technology comfortably over time without making a huge upfront investment.

Our innovative range of finance solutions remove the need for you to use your own capital to make upfront payments. These solutions can be customized according to your cash flow requirements and can be tailored to incorporate any additional machinery and technology, along with BRAUMAT.

Highlights of the future-oriented BRAUMAT V8

If you want to know more about how your brewery can benefit from the Siemens BRAUMAT V8 with our financing options, get in touch with our team here.