Control of Dissolved Oxygen (DO) during Beer Processing

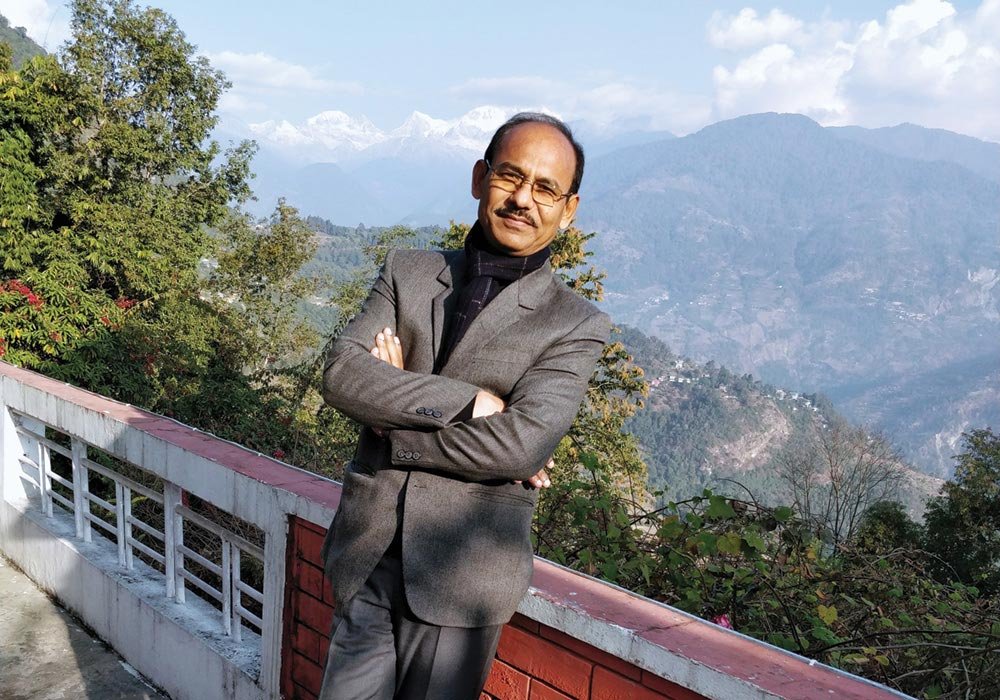

Bijay Bahadur has more than 30 years of experience in Indian/multinational breweries, IMFL bottling plant and brewery green field and brown field projects and factory operations.

Author of Brewing – A Practical Approach, is for practicing brewers, students pursuing careers in Brewing Science and consultants who provide technical advice to the breweries and entrepreneurs. He is a FELLOW of The Institute of Engineers (India) and Chartered Engineer (India), lifetime member of the Indian Institute of Chemical Engineers and Association of Food Scientist & Technologist (India).

He is also selected as Professional Engineer by ECI, New Delhi. Mr. Bijay is currently associated with Yuksom Breweries Ltd (Sikkim) as Factory Manager (Unit Head).

Oxygen is everywhere. We need oxygen to live and it is also a necessary component for brewing beer. Insufficient oxygen is even worse, because yeast will die without oxygen, and then, there is no fermentation of wort to produce beer at all. At different stages of the brewing, except the beginning of fermentation, the contact between beer and oxygen should be limited in order to prevent oxidation of compounds that impart positive flavour attributes and / or the formation of compounds that cause negative attributes.

During fermentation, it may be necessary to increase oxygen levels in wort to support yeast activity. Oxygen levels during fermentation still need to be low enough to avoid oxidation of flavour compounds and therefore should be monitored and controlled continuously.

Oxidation before fermentation is often referred to as Hot Side Aeration (HSA) while oxidation during and after fermentation is referred to as Cold Side Aeration (CSA). A distinction is made between hot-side aeration (HSA) and cold-side aeration (CSA). The hot side includes procedures from mashing through wort cooling. When the wort is cool, oxygen is added to the wort before the yeast is pitched. At this point in the process, oxygen serves as an invaluable yeast nutrient. However, once the fermentation has started, oxygen returns to being a negative element, and what is referred to as the cold side starts at this point and continues until the beer is consumed.

Presence of oxygen (air) in beer results in oxidation, a major contributor to degrading beer flavour, quality and colour problems in beer. Oxidation also negatively impacts the beer’s shelf life.

The goal of the Brewer is to identify the critical areas in the brewing process where oxidation is likely to occur and hence care is needed to prevent oxidation to ensure dissolved oxygen (DO) level in finished beer is kept extremely low.

Dissolved oxygen (DO) is the enemy of the bottled beer and the Brewers should take great care to make sure that DO level from packaging is kept as low as possible. However, the overall exposure to DO during process is more significant than bottle DO alone. Lower DO increases shelf life and flavour stability. Decreased DO levels in finished beer along with reduced energy and CO2 usage is much better for the organization’s bottom line as well as reducing carbon footprint.

Oxygen levels throughout the Brewing Process:

| Brewing Process | Oxygen Level |

|---|---|

| In wort | 6 – 14+ ppm |

| Fermentation | < 0.03 ppm |

| Filtration | 0.001 – 0.2 ppm |

| Bright beer after filtration | 0.001 – 0.2 ppm |

| Beer at the filter | 0.001 – 0.2 ppm |

| Package dissolved oxygen (bottle) |

0.03 – 0.25 ppm |

| Total package oxygen | 0.05 – 0.45 ppm |

The most important sources of air (Oxygen) pickup in the beer processing are:

Transfer between tanks:

There is high initial pickup which is due to turbulent entry to the tank and gets smaller as transfer proceeds and tends to rise again towards the end of transfer. The final rise in DO may be partly due to presence of surface beer which has been in contact with air or to vortexing at the end of transfer.

Carbonation:

Increase in oxygen pickup can be traced during carbonation. Carbonation of beer by one volume of CO2 gas containing 0.05% air can theoretically contribute 0.2 ppm of oxygen (if all oxygen becomes dissolved in beer).

Filtration:

Always DO content increases greatly in the first beer passi ng a newly started filter and decreases as filtration proceeds and the overall increase due to filtration can be kept down usually with carefully working.

Addition of stabilizers:

A ready source of DO is the addition of stabilizing or foaming additions when additives are prepared in water suspension.

It has been found that if insufficient ascorbic acid (antioxidant) is added to the beer, the dehydroascorbic molecule may act as an oxygen carrier and catalyse oxidation of beer, making things worse instead of better.

Addition of recovered beer:

Recovered (residual) beer commonly contains high DO content, some derived from first and last filter runnings and some picked-up by exposure of tank bottoms etc. to air in beer tanks or in sedimentation tank.

At bottling:

Aeration of beer during filling and in the filled bottle occurs in two different ways – absorption which takes place as the beer is filled and absorption from air lift in the head space, and the amount of oxygen picked-up from each of these sources is almost equal.

Good practices to avoid oxygen pickup:

- Minimize cold side transfers, and purge both the lines and the target vessel while transferring

- When transferring, and if possible, do it by pushing with CO2 from one vessel to another, not by pumping or by gravity. Keep the pressure above ambient just a bit

- All joints and unions in the transfer lines must be tight, and the line itself must be designed in such way that excessive beer flow velocities and turbulence are avoided

- CO2 should be used in place of air for top and back pressure

- A light carbonation (0.1 – 0.2 % v/v) may be given during transfer and excess CO2 blown off from the tank, carrying air with it before it has time to react. However, too much carbonation should be avoided as it may lead to loss of desirable volatiles

- Beer should enter the receiving tank at low velocity so that turbulence is prevented

- Transfer lines should be filled with water before commencing any transfer and this water may be pressed out by CO2 before beer enters the line

- High purity of CO2 gas for carbonation of beer and the pressure of CO2 gas during carbonation must be higher than the pressure of the total dissolved gases in the beer to prevent bubble formation

- Precoating of kieselguhr filters with beer (use of beer can lead to foaming) rather than water or by using de-aerated water or the water used to sterilize the filter

- Additives should be prepared in deaerated water

- Extensive washing of recovered (residual) beer by CO2 gas prior to reprocessing

- Addition of correct dose of antioxidant such as ascorbic acid in order to compensate for processing faults and to take the place of careful process control

- Uniform foaming up the bottles by beer fobbing device (a high pressure and temperature water jet down through the surface of the beer in the neck of the bottles

- Filler should not be run at higher speeds than its designed speed otherwise this will give great turbulence leading to higher pick-up even when CO2 is used for counter pressure in filler

- Regular inspection and cleaning of the filling valves is essential especially when these incorporate mesh screens which can retain sharp particles of beer stone, glass chips, anything that can obstruct the smooth flow of beer in the filler or damage the valve surface may lead to turbulence which will entrap headspace air that cannot be removed by beer fobbing device (over foaming) after filling

- The filling operation should be carried out as uniformly as possible in respect of filling rate, filling level and counter pressure conditions since variation in any of these caused stop-and-start operation usually lead to higher air content

- There must be adequate accumulations of bottles both before and after the filler, and the bottle lifts and the conveyor between filler and crowner for smooth operation in order to avoid jerks and knocks

Conclusions:

Control of oxygen (air) is important at different stages of brewing. It affects yeast health and productivity as well as the oxidative formation and degradation of flavour compounds, affects colour and shelf life of the beer. Careful monitoring of oxygen levels as well as taking measures to control oxygen levels are essential to quality control during beer production.It is recommended the best of all antioxidants – namely Brewer’s Yeast. The role of yeast as an antioxidant and stabilizing agent during an active/vigorous secondary fermentation or conditioning of beer in storage tank, they are much less liable to oxidation and are more stable. One fact is clear that Brewers can exercise a great deal of control over flavour stability, quality and colour by observing proper brewing techniques.