Bringing Art to Craft

Abhishek Chinchalkar & Harshit Thakkar

Co-Founders of Bombay Duck Brewing

A small craft brewery in Mumbai producing hand crafted, artisanal ales believing in innovation, experimentation and collaboration. Their products have an audacious focus on flavour with an emphasis on creativity and innovation while incorporating local ingredients, which leads to virtually limitless styles of beer with strong ties to the local community. This global phenomenon is often dubbed as the craft beer revolution and being at the forefront of a burgeoning craft beer scene in India, Abhishek Chinchalkar and Harishit Thakkar set out to take this movement a step further by taking a gastronomic approach to beer which complements the vast diversity of Indian food and giving it a culinary appeal taking it beyond just a beverage meant for imbibing. Divyesh Patil, PKSBE in conversation with Harshit Thakkar on the Bombay Duck Brewing Co. story.

How did you start brewing? What’s your story?

We’ve know each other from grad school at the University of Michigan. Being college students, we used to joke about starting a brewery someday, so we’d never have to pay for beer again, but that plan got a little side tracked after everyone graduated in 2008 and got jobs. We graduated in the middle of the recession and Sohil and Harshit worked briefly in New York before moving back to India while Rahul and Chinsi stayed back in the US. We had dabbled a bit in homebrewing in grad school, but the big break came when Chinsi ended up moving to Dallas, Texas for a new job he started there in 2012. He rekindled the interest with a homebrew kit that was purchased online and brewed the first batch in 2012, shortly thereafter Chinsi discovered a local homebrew club, the North Texas Homebrewers Association and that’s when the hobby really took off. Weekends were spent brewing at friends’ backyards grilling barbeque and brewing beer by the pool side while the weekdays, in planning recipes in anticipation of the weekends.

Why did you get in this industry? And in particular why did you open a production brewery?

Brewing for us started out as a hobby and it seemed like the obvious choice to try and make a living out of when we got bored of our corporate jobs. Call it a mid-life crisis or the burning desire to go stick it to the man after working most of our twenties in typical corporate jobs in tech consulting and finance. We decided to go down the route of setting up a brewery instead of a brewpub because we wanted to focus on making beer and not running a restaurant, which is a completely different business. The idea was to bootstrap and keep our overheads low till we could build enough traction with our audience.

What was the time taken from conception of idea to execution? What was the journey like?

Sometime in 2014, Harshit happened to be visiting Texas on a business trip and that’s when the plan was set in motion. Given the landscape in India in 2014, we thought it was crazy enough to work after seeing the success of Gateway, Doolally and Arbor Brewing, which happens to have a connection to Michigan as well. Sohil has a background in finance & investments while Harshit had previously worked in a couple of startups, one of which had gotten acquired recently. Between the four of us, we felt we had the resources and experience required to jump into the beer business. Sohil and Harshit did most of the legwork around getting things going in India while Chinsi and Rahul decided to get more exposure with some of the more technical aspects of the brewing side. As a part of our research, we ended up talking to a lot of local brewery owners in Texas and Colorado and got our foot in the door volunteering at local breweries on weekends and holidays. A couple guys at Chinsi’s homebrew club were, at the time, in the process of setting up their own commercial operations and that gave us a great window into the nitty gritties of turning this hobby into a business. Chinsi moved back in 2015 and we signed a lease on a property in 2016 and have been at it since then. It’s been a friends and family affair so far.

We wanted to build something that would be uniquely ours and designed from the ground up to match our style and philosophy of brewing. We took inspiration all the way from 18th century manual brewing systems to the latest microprocessor controlled, IoT enabled automated brewhouses. A great analogy here would be buying a soaped-up MacBook off the shelf as opposed to building a gaming PC part by part, customizing every little aspect of it right from the chipset to the GPU. If you have the money, buy the MacBook but where’s the fun in that? We felt that getting down to the nuts and bolts, not only put into context our knowledge of brewing but also helped us appreciate the modern technological advances and their evolution from age old practices that have been followed for centuries.

What is the bottleneck process in setting up a production brewery in India?

Getting funding is one of the biggest challenges to setting up an alcohol business in India. Availability of small business loans to set up a brewery is something which is quite challenging, partly due to the entrenched attitudes of the decision-making authorities towards alcohol and the risk involved of operating in a highly regulated environment. In absence of those, self-funding is the only viable option and fortunately for us we were able to manage it through our savings and some benevolent friends and family.

How was your experience of obtaining licenses? What would be your suggestion to the Indian government in respect to streamlining the process?

It has been quite an interesting experience. Being a bootstrapped start-up, we do not have the luxury of surplus cash and so we decided to do it ourselves without hiring an agent or going through a consultant. To be fair we did have access to a wealth of knowledge thanks to some of the other craft breweries that went through the process before us like Doolally, Independence, BrewBot and Gateway but for the most part, the process is straightforward, timelines notwithstanding. Sure, the laws are archaic and seem completely anachronistic in 2018 but like everything else, they are changing. The current rules of engagement seem to have been written around a model which favours ownership of the place of business which keeps the barrier to entry quite high, which is bad for the long-term sustainability of the industry. A digital process of obtaining licenses can streamline a lot of the paperwork that goes into setting up a brewery in the state of Maharashtra. There are a lot of redundant checks built into the system and a digital process like the one for your passport can help cut down some of the delays resulting from physical folders moving across different departments and jurisdictions. The government offices seem to be understaffed for the number of applications they receive and that ends up in further delays at a very granular level.

From a policy standpoint, I would like to see the state and local governments do more to promote small breweries that create jobs, support local agriculture, as well as bring in tourism revenue in the state. For example, the state of New York, has a farm brewery policy which grants local breweries, tax breaks and concessions for using locally grown hops and malts as a way of supporting local agriculture.

Why did you go for rebranding? What is the idea behind your current brand?

Why did you go for rebranding? What is the idea behind your current brand?

We’ve been working on the branding bit for about 8-9 months. The initial logo was a placeholder of sorts since we were still working on the licenses and other operational requirements to get going. It so happened that the new brand identity release coincided with our going commercially live.

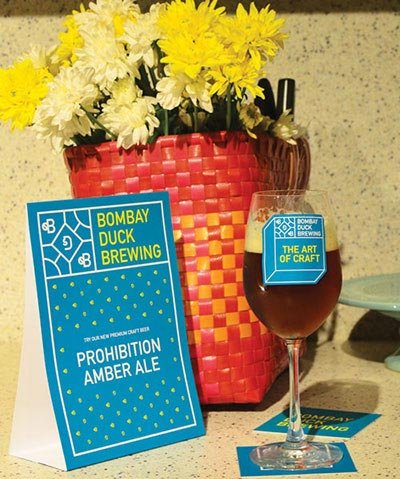

The first step in creating the new brand identity and visual language for Bombay Duck Brewing came from our belief strongly rooted in the four pillars of authenticity, community, innovation and reliability that we as a company believe in. We wanted a visual language that mirrored these values that we aim to always stand by, while reflecting our deep connection to our beloved Bombay. Starting from this as the stepping stone, we brainstormed a lot of ideas, went on a lot of photo walks around the city for inspiration. Our graphic designer was at the time based in Croatia, and has also lived in Bombay for a few years. So we’d send him the images that we collect and we would bounce ideas off of each other looking at these images and through our memories and conversations.

The first step in creating the new brand identity and visual language for Bombay Duck Brewing came from our belief strongly rooted in the four pillars of authenticity, community, innovation and reliability that we as a company believe in. We wanted a visual language that mirrored these values that we aim to always stand by, while reflecting our deep connection to our beloved Bombay. Starting from this as the stepping stone, we brainstormed a lot of ideas, went on a lot of photo walks around the city for inspiration. Our graphic designer was at the time based in Croatia, and has also lived in Bombay for a few years. So we’d send him the images that we collect and we would bounce ideas off of each other looking at these images and through our memories and conversations.

While staying rooted in the old ways of the city, as an Artisanal craft brewery brewing old and new global beer styles; we also wanted to show that we’re completely in tune with how the city is growing into a cosmopolitan of the modern times. The visual identity’s concept had to represent mixing the old with the new, bringing art to craft, focusing on the artisanal skills while retaining the unique vibe of Bombay. A lot of Photo walks across the city, and brainstorming sessions later, the visual reference came through fretwork — by taking an old motif and creating a modern twist to it, showcasing where we come from and that we take pride in it. Craft beer like fretwork takes time to perfect: symbolising how as a craft brewery we always strive to bring art to our craft.

Fretwork is one of the key visual cues of Bombay – it is something unassumingly beautiful and is seen across the city in styles ranging from Art Deco to Victorian, Gothic to Mughal and beyond. The decorative grills and fretwork is one of the cornerstones of the art + craft movement, combining the craft of metal and wood work with the art of shapes and patterns created to elevate the seemingly ordinary object.

A thing of ‘functional ‘everyday’ beauty. That is exactly how we wanted people to feel every time they savoured one of our beers. And we found a visual/brand language that subtly evoked exactly that! The interesting thing is after working on our brand identity, we happen to notice and admire the fretwork in our daily lives a lot more! For instance, a drive through the Wadala – Matunga neighbourhood is suddenly full on renewed excitement, checking out the amazing grillwork building after building. It’s like discovering something that was always present around you. Exactly what we wanted to achieve, something inherently Bombay in a very subtle way. One of the very many visual treasures this city offers hidden in plain sight – one just has to be willing to look harder.

How do you differentiate yourself from other breweries?

We pride ourselves in being a radically flat organization with no titles. Corporate hierarchy, often, leads to bottlenecks in decision making and we have all had jobs in the past where the managerial chain of command felt counterproductive, unwieldy and unnecessarily bureaucratic. We are a product company at the end of the day and the kinds of decisions we end up having to take daily are driven by keeping in mind the customer and our core values as a company. Consequently, we chose to compartmentalize the organization based on cross-functional teams with specific focus who have complete ownership and accountability along with the relevant skill set to accomplish what they set out to. We believe the best ideas come from the bottom-up and not top-down. In most top-heavy companies though, the ideas come from the top, and the inherent hierarchy can mean artificial authority wins and not the best idea. For instance, an idea for our next greatest beer doesn’t necessarily have to come from the brewing team. We have a small pilot system which is our test kitchen that everyone in the organization has access to that is used for new recipe development and formulation. If someone has an idea for a beer that they want to try out, all they have to do is to reach out to the right people with the necessary skill set and have a go at it.

The focus on sustainability is another aspect that is very near and dear to our hearts that we hope to differentiate ourselves by. Right from sourcing ingredients to the conscious steps we take to minimize our environmental footprint. Being a small brewery often means that this comes at a prohibitively high cost of doing business but I think that is one of those things which not negotiable.

Your equipment is locally fabricated or imported? Reason for the same?

We decided to design and build our equipment ourselves from scratch. It took us about two years in research and development, but it was quite rewarding and worth all the effort. At the end of the day we wanted to build something that would be uniquely ours and designed from the ground up to match our style and philosophy of brewing. We took inspiration all the way from 18th century manual brewing systems to the latest microprocessor controlled, IoT enabled automated brewhouses. A great analogy here would be buying a soaped-up MacBook off the shelf as opposed to building a gaming PC part by part, customizing every little aspect of it right from the chipset to the GPU. If you have the money, buy the MacBook but where’s the fun in that? We felt that getting down to the nuts and bolts, not only put into context our knowledge of brewing but also helped us appreciate the modern technological advances and their evolution from age old practices that have been followed for centuries.

Fortunately, we have been lucky enough to find and work with some amazing folks from the craft brewing community who have helped us learn from the mistakes they made, and a huge part of that credit also goes to the amazing guys over at Prism Brewcraft, who are as passionate about engineering as we are about making beer.

What are the major issues you face in daily operations?

The most obvious one would be the regulatory compliance, aka paperwork, we end up dealing with on a day to day basis as a small business. To give you a loose analogy between a craft brewery and a small restaurant, imagine having to get physical approvals from a state inspector at every step of the process right from procuring ingredients, cooking the dish, plating it, serving it and finally billing the customer. Now imagine if you’re running a delivery kitchen and every time you had to ship an order out to a customer you had to catch hold of your local food inspector and have him approve and sign off on it. Not to sound discouraging but next picture a world where the customer pays you 60 days after consuming the food, but you still end up paying tax on it the day you produce it. Having your own retail outlet will help you ease some of the cash flow issues but that comes with its own set of challenges, not to mention the hefty capital investment required. The margins are razor thin and the hours are long but there is an immense satisfaction in sitting down at the end of the day and having that pint of beer, enjoying the fruits of your labour.

The other major issue craft brewers face is about improper handling of beers. Like others who came before us, we choose not to pasteurize the beers or use any preservatives and instead rely on a cold chain in the interest of retaining some of the flavours that would otherwise be lost in the process of pasteurizing. Think about it as buying UHT milk in a tetra pack from a grocery store that’s been sitting on the shelves for weeks if not months, as opposed to buying fresh milk from your neighborhood dairy. Craft beers, if handled well, have a decent shelf life but it gets hot in Mumbai for the most part of the year and it takes very little for the beer flavor to start deteriorating.

How do you come up with new brews?

Beer is the perfect marriage (if there is such a thing!) of art and science, just like cooking, and that is one of the underlying philosophies around the beer we brew. We’ve always been fascinated by the sheer number of ingredients available in the Indian subcontinent which haven’t yet been explored in the context of beer and while that holds a lot of promise, a lot of these come with their own set of challenges around sourcing and incorporating them in recipes. Travelling is a big part of our inspiration as well and it’s a great way to explore more of the country and immerse ourselves in different cultures and traditions around food. Brewing for us is as much about a journey in self-exploration as it is about understanding the deep connection it has to the culture and environment it is a part of.

What according to you is the most crucial process in the production of beer?

It would be the fermentation. As they say, brewers make wort and yeast makes beer, our job as brewers is to ensure the yeast is happy so that it can do its job well. Time is the fifth, but often overlooked ingredient after malts, hops, yeast and water. Unlike in wine, most of the flavour of the beer is yeast driven and given the right temperature and conditions, they can produce some amazing results. Being a production brewery, we have the space and resources to engage in some cool projects which involve longer aging, mixed fermentation for typically a year or more with different yeast and bacteria strains, more laborious fermentation profiles, blending, laagering, barrel aging, etc.

Why are there no or very few maltsters in India?

There actually are a handful of maltsters in northern India but the beer market till date has mostly been dominated by insipid mass produced macro-lagers, the mechanics of producing malts for which have purely been driven by the economies of scale. Most maltsters usually cater to the large industrial breweries, understandably so and the emphasis hasn’t been as much on flavor as it is on keeping costs low.

As a result, there hardly exist any craft maltsters that produce specialty malts in small batches, which are better suited for some of the traditional beer styles small, independent breweries like us focus on making.

What do you think is the future of this industry? What according to you is the next big thing happening in craft beer industry in India?

The next big thing must be more locally grown ingredients. Beer brewing, at the end of the day, started out as an allied value-added agronomic activity to farming and like how the wine industry spawned an interest in viticulture, we would like to see more farmers taking an interest in growing barley, hops and other ingredients which can be showcased in locally made beer. For example, our friends at Great State Aleworks have been experimenting with using millets to brew beer while the pioneering guys at Doolally have tried to grow and malt barley locally in Maharashtra. We brewed a batch with a local variety of rice last year, popularly known as Ambemohar and that was received well. On a global scale, that seems to be the trend as well where consumers tend to prefer more locally made stuff as opposed to something that is shipped half way across the country or a continent.

There definitely seems to be a lot of interest in the beer market in India and consumer education and awareness is the key here in order to ensure a long-term sustainability of craft breweries. A lot of the global conglomerates are launching new brands from their portfolio and we hope that this leads to better infrastructure, right from the distributor to the bar.