Sustainability – just a slogan?

Not for Joh. Barth & Sohn, the leading provider of hop-related services!

Dr. Reinhold Kugel

Joh. Barth & Sohn

Dr. Reinhold Kugel grew up on a hop farm and studied Agricultural Science and Economics at Hohenheim University, Germany. From 1988 to 1990 he worked for the German government on the “Philippine-German Biological Plant Protection Project” in Davao City, Mindanao, Philippines. Reinhold has been working out of Germany for the Barth-Haas Group since 1991. He is responsible for Product Safety and Quality Assurance at Joh. Barth & Sohn, heading the purchasing office in the Tettnang growing area and serving brewery customers in Japan, Korea and the Philippines. In addition, he is working on international pesticide residue harmonisation issues for the German Hop Industry Association. Reinhold is also a member of the EU Commodity Expert Working Group Hops (CEG). In 2011 he became a member of the Barth-Haas Sustainability Team which he has led since 2015.

For many companies today, it is a question of etiquette to take up the cause of sustainability. However, in a company like Joh. Barth & Sohn, a successful market player now in its 8th generation, sustainability has been part of the corporate DNA ever since its foundation. “As a family-run company, we at Barth have always orientated our decisions in part to the question of what state we will leave the company and the environment in for the next generation.” This is how Stephan Barth, managing partner of Joh. Barth & Sohn, describes the company’s sustainability gene. “That is also why we developed the seal: Sustainable – since 1794!“ (Barth)

Taking Joh. Barth & Sohn as an example, the following is intended to show how a family-owned company has developed its sustainability concept. A separate article will then address the question, for example, of what consequences this orientation to sustainability has for the growing and processing of hops as a raw material and for the hop producers them Creating clear personnel responsibilities.

Even though sustainability is part of the DNA in a family-owned company, it is not enough to rely on that alone. Therefore, Barth has taken a systematic approach to the subject of sustainability.

First, the organisational groundwork was laid and a sustainability team established in order to promote the subject within the company. The sustainability team has two main functions: to provide the impetus for sustainable projects and to be a point of contact that employees can approach with ideas and questions. The sustainability team consists of representatives of the Executive Board, Quality Management, Purchasing, Sales, Marketing, Controlling, Technology and Research. “This mix of representatives from all the divisions and departments in the company in the sustainability team is a key prerequisite for implementing the concept of sustainability in the company”, says Reinhold Kugel, the head of the sustainability team.

First, the organisational groundwork was laid and a sustainability team established in order to promote the subject within the company. The sustainability team has two main functions: to provide the impetus for sustainable projects and to be a point of contact that employees can approach with ideas and questions. The sustainability team consists of representatives of the Executive Board, Quality Management, Purchasing, Sales, Marketing, Controlling, Technology and Research. “This mix of representatives from all the divisions and departments in the company in the sustainability team is a key prerequisite for implementing the concept of sustainability in the company”, says Reinhold Kugel, the head of the sustainability team.

Systematising stakeholder expectations

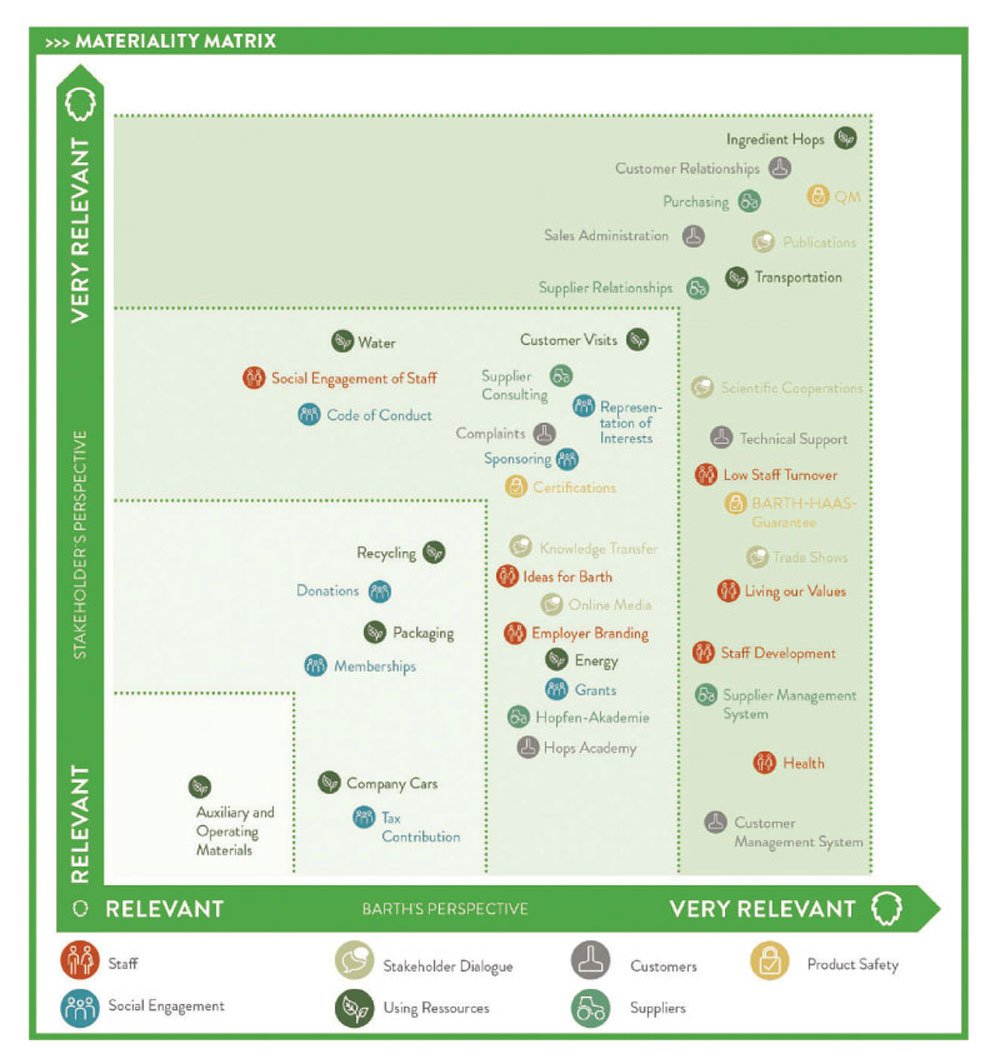

Personnel responsibilities are one thing, but what topics have priority? Where does the company have to start; where are sustainable decisions particularly needed? What do the stakeholders expect of the company – and what does the company expect of them? Barth’s most important stakeholders are its employees, hop suppliers and customers, primarily breweries. Then there are associations, the scientific community and public authorities. The stakeholders’ responses have been systematised and collated in a materiality matrix (Fig. 1). This has made it possible to classify the relevance of individual points systematically. The matrix shows clearly where the stakeholders see a need for action. This means that the “only” things lacking for implementation were the right instruments and processes with which to work on and document the issues.

The sustainability team has two main functions: to provide the impetus for sustainable projects and to be a point of contact that employees can approach with ideas and questions. The sustainability team consists of representatives of the Executive Board, Quality Management, Purchasing, Sales, Marketing, Controlling, Technology and Research. “This mix of representatives from all the divisions and departments in the company in the sustainability team is a key prerequisite for implementing the concept of sustainability in the company”, says Reinhold Kugel, the head of the sustainability team.

The materiality matrix – what is relevant for the stakeholders and the company?

Initial successes on the way towards even greater sustainability.

Together with all our employees, we have already been able to complete a number of projects that have had a positive influence on the company in ecological, economic and social terms. One key element in this has been the stakeholder dialogue between all the internal and external groups of people who are in any way affected by our company’s activities. The extent to which the idea of sustainability has spread throughout more and more areas of the company can be seen in many small details. Most of the data are taken from the 2015/2016 Sustainability Report because more recent figures are not yet available. However, some individual interim results show us that the path chosen is obviously the right one because further successes have been achieved on the way towards greater sustainability:

Together with all our employees, we have already been able to complete a number of projects that have had a positive influence on the company in ecological, economic and social terms. One key element in this has been the stakeholder dialogue between all the internal and external groups of people who are in any way affected by our company’s activities. The extent to which the idea of sustainability has spread throughout more and more areas of the company can be seen in many small details. Most of the data are taken from the 2015/2016 Sustainability Report because more recent figures are not yet available. However, some individual interim results show us that the path chosen is obviously the right one because further successes have been achieved on the way towards greater sustainability:

- In our current project “From the road to the rails”, we have increased the proportion of transport by rail compared to transport by truck from 10% to 46%.

- Following the introduction of a new online meeting tool, the number of business-related flights has been reduced significantly.

- On the way to greater transparency and an even more intensive dialogue with stakeholders, a Code of Conduct has been developed, published and implemented.

- A customer management system has enabled us to conduct an even more intensive dialogue with our customers.

- In our processing plants, by installing a heat recovery system we have been able to reduce the annual oil consumption of the plants connected to it by up to 90%.

- Barth actively supports the non-profit Hopfenring in the further development of the “Sustainability in Hop Growing” system in order to motivate others.

- A very topical success story is our involvement in the pilot project “Sustainable supply chains” organised by the Bavarian Environment Ministry, for which only 10 companies in all of Bavaria have been approved.

Example: the social factor

Due to demographic developments in Germany, it is becoming increasingly more difficult for companies to recruit suitable skilled workers. “If I am to motivate well-qualified employees for whatever position, I have to offer them more than just regular salary payments and entitlement to annual leave.” (Regine Barth) To get the best performance from employees, it is also all the more important to create the right environment. This, too, is part of a company’s sustainable business practice.

- The following key figures illustrate the developments (data base: 2015/2016):

- Two thirds of the employees of Joh. Barth & Sohn have full-time employment contracts.

- The turnover rate among our employees is only three per cent.

- Well over half of the workforce are women.

- More than 50 per cent are between 30 and 50 years old.

- The time per employee for training and further professional development is currently being further increased to 22 hours.

- A company health management programme is being introduced in our management process.

- Employees who take part in voluntary work in their free time receive support, either of a financial nature or through donations in kind or time off work for this activity.

Example: stakeholder dialogue

Dr. Reinhold Kugel, the sustainability officer at Barth sums up the point of the stakeholder dialogue quite simply: “To find out what is expected and to communicate what we are doing”.

One example is the “Ideas for Barth” project, through which employees are involved in the company’s sustainability strategy. They are motivated to check all processes both within and beyond their operating environments with regard to sustainability and to submit their suggestions, comments and ideas for improvement. A number of improvements have resulted from this project, such as increased efficiency in the warehouse serving small customers and in the dispatch of samples, or the reduction in the use of paper in the exchange of data with internal and external labs.

Barth has developed an appropriate channel for each type of information, be it the globally unique Barth Hop Report, the Hop Science Newsletter, technical or scientific publications, the Hop Flavour blog, the Humulus Lupulus columns or one of many others. It goes without saying that all this information is also available for download on the website www.barthhaasgroup.com.

In order to ascertain customer satisfaction, Barth conducts an online customer satisfaction survey every two years. This allows the company to gather suggestions regarding improvement potential to further optimise customer service. On a scale of 1 (inadequate) to 5 (excellent) our last overall score was 4.3.

Example: technical and scientific dialogue

Any company that, depends on the latest findings in all hop-related fields, has to actively support technical and scientific dialogue, for example by cooperating with universities, but also by offering stakeholders further training through its own seminars.

The Barth-Haas Hops Academy was founded in order to create a better understanding of the complexity of the hop and of its potential. Its mission is to convey detailed knowledge about the use and effects of hops in the brewing process in one to three-day seminars. The Hopsessed module, which was developed in-house, covers education in and evaluation of aromas in hops and in beer.

The Barth Hops Academy’s offerings are focused on hop producers. The Academy provides information on hop growing and offers courses on business management topics, the legal environment or requirements regarding sustainable farming.

Last but not least, Barth supports research through grants for young students. The grants are intended to encourage new approaches in research dealing with hops and their application potential. Six grants have been awarded every year since 2007.

What’s next?

What remains to be done? To become (even) better and more sustainable, of course. But the biggest project at the moment is certainly to extend sustainability reporting to all the companies in the Barth-Haas Group. This means gathering data on a global scale and reporting on our subsidiaries in England, the USA and Australia in accordance with the latest GRI standards.