Pursuing Sustainability, Smart Deployment of Energy Flows from Krones

Craft brewery with EquiTherm, which exponentially reduces the use of primary energy in the brewhouse.

Authors

Mayank Sood

Deputy Manager – Sales-KRONES India Pvt Ltd

VGS Babu

Head Sales – KRONES India Pvt Ltd

This concept prevents a surplus of warm water in the brewhouse, since excess energy in the energy circuit can be effectively utilised. As a result, the quantity of wastewater involved is equally downsized.

KRONES has recently succeeded in Indian Craft brewery market with the orders of two dedicated brewhouses in Nepal. KRONES has pushed itself hard on the competition with its proven brewing technology from KRONES Steinecker. Both brewhouses are equipped with EquiTherm, a patented technology from House of KRONES which has the potential to save up to 30% of the primary energy.

The Principals of EquiTherm Technology:

- Energy is recovered on a wort precooler at approximately 96°C

- Extraction of a defined amount of heat at the wort cooler

- The mash is heated up with energy from the first stage of the wort cooler

- Provision of the required heat flows at the mash tun is regulated precisely

- The hot water returns is temperature-dependent and then fed into the energy storage tank

- Solution concepts are for infusion and decoction systems available

EquiTherm also reduces steam consumption and peak loads in the brewhouse, thus providing the possibility for customers to downsize the boiler. A 200,000-hectolitre brewery can, for example, save up to 400,000 kilowatt-hours of thermal energy a year and possibly also save electrical energy. This concept prevents a surplus of warm water in the brewhouse, since excess energy in the energy circuit can be effectively utilised. As a result, the quantity of wastewater involved is equally downsized.

At a Glance Advantages of EquiTherm

- Reduction in primary energy requirements, saving of resources

- Reduction in peak loads in boiler systems

- Reduction in electric connected loads as a result of smaller cooling systems

- Smaller boilers and cooling systems can be installed in new projects

- Elimination of excess hot water and optimization of water management

- Flexibility in terms of the mashing in temperature, independently of the available volume of hot water

- Reduction in the heating agent temperature to below 100°C, meaning reduced thermal stress for the mash and no fouling on the heating surface

- Flexibility in the choice of total evaporation, excess energy from the vapors can be recycled

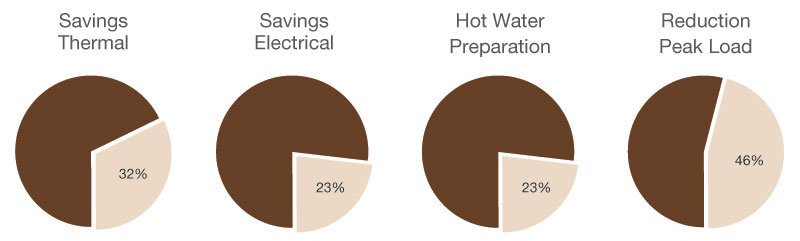

Savings at a glance with EquiTherm

Customer Testimonial

Managing Director, Yak Brewing Company – Nepal

KRONES Steinecker has been at the forefront in brewhouse systems for many decades and with massive energy saving from EquiTherm energy recovery system, we couldn’t have made a better choice than KRONES. The energy-efficient brewhouse had to be also particularly effective in extract production and achieve fast brewing cycles. Therefore, it is prepared for future expansion. All these prerequisites are assured by the KRONES brewhouse, and helped us lower production costs and compete in the heavily price-sensitive market.