Growler 101 for Indians Who Love Local Craft Beer

Chugging beer from cans and bottles is universal. But nothing quite beats the thirst-quenching joy of craft beer, freshly poured at your local microbrewery.

Is it possible to get this freshness in taste, flavours and aroma to-go? Yes, it is. But only with the help of growlers.

Not only that, ever since the pandemic forced hundreds of small, independent craft beer producers and microbreweries across countries to shut shop, growlers have also proved to be a huge blessing in relieving them from a long, dry spell of zero income.

Today, Karnataka has become the first Indian state whose microbreweries have been granted permission to sell existing craft beer stocks through growlers (thank you CBAI!). But what exactly are growlers? Here’s the 101.

History

The first patent substituting ‘beer cooler’ for the word ‘growler’ was registered in the U.S. in 1900. However, the concept was in use long before that, as early as the 1800s – when local taverns, breweries or saloons used to fill beer in metal pails or buckets for consumers (mainly women and children) to take back home (to husbands and fathers) for consumption.

The 1920s Prohibition era seemingly threatened to end the growler trend once and for all. Thankfully, it made a comeback after 1933.

What’s with the name, anyway?

The most common story behind the name ‘growler’ is that the lids on these metal cases caused a rumbling sound every time they rattled and the carbonation escaped, thus generating a sound that sounded similar to a growl. Terms like ‘rushing the growler’ and ‘working the growler’ were coined to describe acts of retrieving beer from a bar using pails or growlers.

The Modern Growler Makeover

Growlers were given a makeover in the 1950s and ‘60s, where metal pails were substituted by waxed cardboard containers. By late 1960s, bars began selling beer packaged in plastic containers.

In the 1980s, Charlie Otto, founder of Wyoming’s first modern microbrewery, Grand Teton Brewing, who didn’t even know what growlers were until his father told him about them – desperately wanted to figure out a way to sell his draft beer to-go. With the help of a silkscreen machine, he started printing his logo onto gallon glass cider jugs. That’s how the modern beer growler was eventually born.

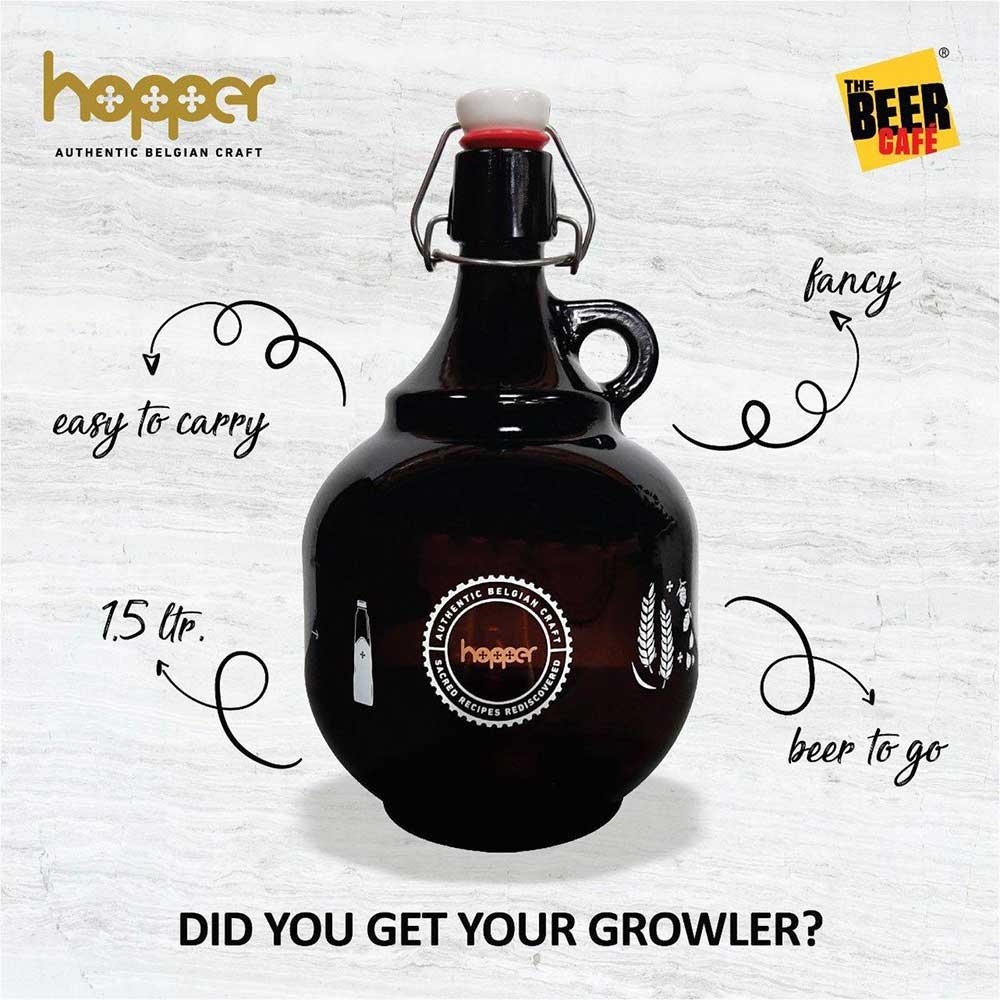

Today’s growlers have definitely evolved from the basic glass jug to keep up with the times. Today, they’re available in a variety of sophisticated designs, shapes and sizes. From solid promises of temperature control to guaranteeing perfectly preserved carbonation and freshness for weeks, growlers today have helped transport craft beer far beyond local microbrewery walls. Be it matte-finished, bright-coloured options or heavy-duty, stainless steel, vacuum-insulated vessels, there’s a style for every kind of beer-lover.

Today’s growlers have definitely evolved from the basic glass jug to keep up with the times. Today, they’re available in a variety of sophisticated designs, shapes and sizes. From solid promises of temperature control to guaranteeing perfectly preserved carbonation and freshness for weeks, growlers today have helped transport craft beer far beyond local microbrewery walls. Be it matte-finished, bright-coloured options or heavy-duty, stainless steel, vacuum-insulated vessels, there’s a style for every kind of beer-lover.

However, regardless of what material growlers are made of (whether it’s glass or stainless steel, plastic or even ceramic), everyone – both brewers and consumers – need to remember that these are pressurised containers. As long as the container is able to withstand the pressures exerted by carbonated beer as well as filling method, you’re good to go!

Yes, Growlers Are Sanitary!

It’s fairly easy to keep growlers clean but this is a combined effort on both the brewers’ and the consumers’ sides.

Just as brewers are responsible for filling their beer into clean growlers, ready to be picked up by customers, beer drinkers who own growlers or are “borrowing” one from the local microbrewery/ craft beer producer are equally responsible for maintaining and caring for these containers.

Just as brewers are responsible for filling their beer into clean growlers, ready to be picked up by customers, beer drinkers who own growlers or are “borrowing” one from the local microbrewery/ craft beer producer are equally responsible for maintaining and caring for these containers.

How To Keep Growlers Clean

- Growlers may be cleaned using detergents that are not oil or fat-based. Proper detergent ratios should be used for cleaning so as to not leave behind any unpleasant, chemical aromas that could interfere with that of the beer.

- Brushes can be used to assist in the cleaning process. However, brushes with exposed metal surfaces are a strict no-no when it comes to cleaning ceramic or glass growlers.

- Once cleaned, growlers should be allowed to air-dry completely and should be stored unsealed with the lid off to allow any residual moisture/smells to evaporate from the container.

- After cleaning, growlers need to be sanitised, preferably with trichloromelamine, quaternary or iodophor-based products that are generally used for glassware.

- Never try to fill frozen growlers. Instead: pre-rinse empty growlers immediately before filling with cold water.

Growler-Filling Hygiene Protocol

Basic hygiene goes beyond growlers and begins with draught beer lines being cleaned at a minimum of every two-weeks as outlined by the the Brewers Association Draught Beer Quality Manual’s recommendations. Additionally, any faucet or filling tube used should be thoroughly rinsed, cleaned, sanitised, and then air-dried after each growler fill. A well-designed, well-executed maintenance plan should be put into place at each microbrewery to further ensure a hygienic, trouble-free draught system operation that delivers fresh, flavourful beer.

Consumer Education About Handling Growlers, Post-Filling

- Growlers should be opened within 24-72 hours of filling and the beer should be consumed within hours after opening while of course, taking care to drink responsibly.

Why: Brewery studies have shown that beer quality begins to suffer pretty much immediately after filling. Not only that – carbonation, mouthfeel and the hallmark flavours of your favourite beer brand begin to degrade within as little as 24 hours, while stale flavours become even more obvious within 72 hours.

- Filled growlers should always be stored in cold, dark places.

Why: An increase in temperature can increase pressure and can cause a growler to burst, while exposure to light can damage the beer by causing it to skunk.

- Once empty, growlers should be thoroughly cleaned, sanitised, rinsed and allowed to air-dry immediately. Cleaned growlers should be stored unsealed with the lid off.

Why: This will allow any residual moisture and unpleasant aromas to evaporate from the container.

- Only use growler containers specifically designed for packaged carbonated beer, and ask the container supplier to verify that the pressure rating is equal to or greater than the pressure from the carbonation in the beer being filled. Also, always leave a 5 percent headspace or fill to the manufacturers’ recommended fill line if one is shown.

Why: Filled growlers can shatter or explode if allowed to warm or freeze, especially if they are overfilled.

Other important things to remember

Visually inspect every growler before filling. Do not fill glass or ceramic growlers with cracks or chips, those which have been engraved, or older growlers with pitted or unsmooth glass surfaces, as the pressure strength of these growlers will be significantly reduced.

If your growler has threaded screw-on closures, plastic is safer than metal since the former may vent more readily if over-pressurization occurs

Source:

The Brewers Association: https://www.brewersassociation.org/brewing-industry-updates/handling-and-filling-beer-growlers/

Note: The Brewers Association is providing all COVID-19 resources for free so everyone has access to important information to help them weather the pandemic.