Aroma, Flavour & Body form the Gold Standard for Weyermann Specialty Malts

SABINE WEYERMANN

President, Marketing Sales & Public Relations, Beer Sommelier, Weyermann®

Weyermann® Malts established in 1879, with over 138 years of four generations of agrarian family, has given their heart & soul to Mother Earth. They toiled to produce one of the best crops and then convert them into malt categories in the world. With a team of 190 highly motivated and well-trained staff members at Weyermann® ensures that you will always receive nothing but true Weyermann® quality. Fifty of our staff members hold diplomas or advanced degrees as professional brewers, maltsters, brew masters or brew engineers.

Sabine Weyermann shares her views on quality, production processes and competition.

When one refers to quality that should provide benefits to the consumers, then following them becomes the yardstick of assessment:

Benefits of Weyermann® Specialty Malts

- Quality Aspect – Colour Consistency

- Quality Aspect – Clean Malt

- Quality Aspect – True Caramel Malts

- The Weyermann® Bohemian and Belgian Line

In colour consistency that is of importance is tied to the specification. Weyermann® malts are produced to very tight colour specifications!

- CARAMUNICH® Type 1: 80-100 EBC, 31-38 Lovibond

- CARAMUNICH® Type 2: 110-130 EBC, 42-49 Lovibond

- CARAMUNICH® Type 3: 140-160 EBC, 53-61 Lovibond

Brewers can trust in Weyermann® colour-consistency as our malts have:

- No fluctuations in beer colour and aroma

- No adjustments necessary (e.g. blending beers)

Best Quality, when beers are brewed with Weyermann® Specialty Malt

When you compare this fact with other malt supplier then you will find that, large tolerances in colour specifications is evident that will affect the end result in the process of producing beer.

In our view, we strongly believe the only “True Caramel Malt” exhibits full ‘caramel effect’ in terms of:

- Aroma

- Flavour

- Body

Depicted below is a pictorial presentation of –

- What distinguishes a ‘true caramel malt’ from other dark malts?

- Let us compare the process for your benefit?

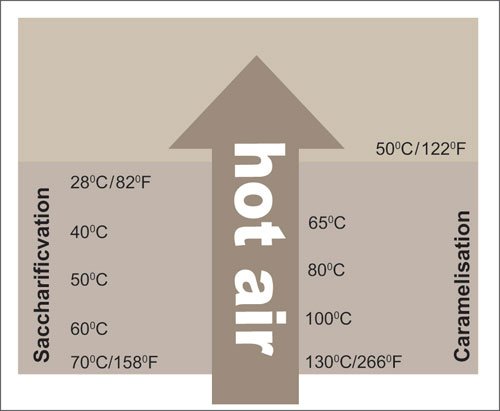

KILN

- Temperature difference in the green malt bed

- Inhomogeneous temperature

- Inhomogeneous saccharification

- Lack of caramelization (not every kernel reaches the required temperature

- Cost-efficient production

- Inhomogeneous malt

- Lack of Caramel flavour

- Lack of typical Caramel malt colour

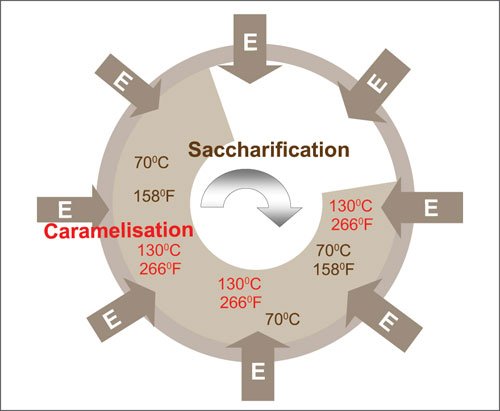

Weyermann offers cutting edge technology in the Caramalization Drum Process:

CARAMELIZATION DRUM

- Homogeneous temperature

- Homogeneous saccharification

- All kernels reach saccharification temperature

- Maximum homogeneity

- Rapid temperature change

- Typical caramel flavour

- Typical caramel malt colour

Let us further elaborate on other Dark Malts available in the market that result into poor-quality of beers that one produces.

Produced in kilns or with “fluid-bed drying” technology:

- Kernels floating on a hot, dry stream of air

- Only dry (not moist) heat available

- No stewing

- Insufficient moisture content

- No enzymatic activity

- No enzymatic saccharification

- No caramelization

- No “true Caramel malts”

- No Caramel flavour or aroma

How to identify True Caramel Malts

- Complete caramelization

- Typical caramel to bready aroma

- Homogeneity

- Glassy, caramelized texture

- No friability tests!

- Enhances foam stability

- Improves aroma and flavour stability

If you are looking at the best results then consider the above factors into account and use Weyermann® True Caramel Malts:

- CARAHELL® – CARARED® – CARAMUNICH®

- CARAAMBER® – CARAAROMA®-Special W®

The most crucial factor that affect the quality aspect is how to get clean malt.

Choose only the largest-diameter kernels for malt production it has better flavour, greater extract efficiency, more efficient processing.

At Weyermann® we follow an efficient 6-step Grain & Malt cleaning process that is unique:

- Step 1: Grain cleaning after harvest

- Efficient aspiration

- Modern grain cleaning and sorting (80 MT/hour)

- When required: careful drying Moisture < 14.5%

- Step 2: Grain cleaning at receiving in Bamberg/Hassfurt

- Efficient aspiration (dust)

- Modern grain cleaning and sorting

- Step 3: Grain cleaning at receiving in Bamberg/Hassfurt

- Aspiration & Sorting

- Only the largest-diameter kernels > 2.5mm (0.098inch) (smaller kernels to feed industry)

- Modern grain cleaning and sorting equipment

- Daily functional check and control analyses (grading) in lab

- Several magnets to trap metal particulate

- Step 4: Grain cleaning before steeping

- Fourth cleaning step before production

- Aspiration and sorting

- Precision cleaning

- Step 5: Malt cleaning after kilning and caramelization and roasting

- Careful malt cleaning and polishing

- Separation of germs and malt sprouts (premium, high-protein feedstuff)

- Daily functional check

- Daily control analyses

- Magnet to remove metal particulate

- Step 6: Malt cleaning before bagging or bulk shipping

- Second careful malt cleaning and polishing Kernels >2.5mm (0.098in) >90% Dust & particulate

- Daily functional check

- Daily control analyses

- Metal detection (unique in the malt industry) Functional check 3 times per day Fe and non-Fe metals

The processes mentioned above result into Weyermann Malts being acknowledged as the Best Choice by the brewer world across the globe!!

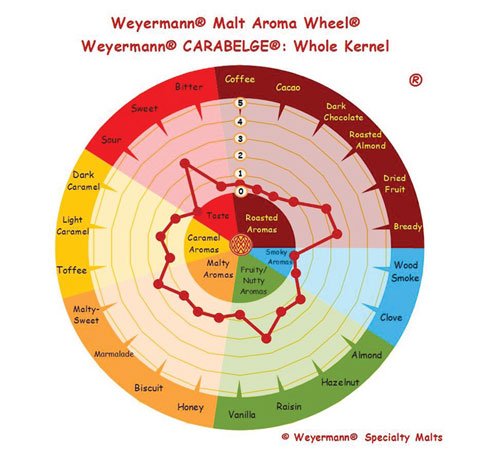

WEYERMANN® BELGIAN-STYLE MALTS

- Weyermann® CARABELGE®

- Colour: 30 – 35 EBC 12 -14 Lovibond

- Produced from: Spring Barley Varieties

- Technology: Caramelization in Weyermann® Roasting Drum

- Character: Mild caramel notes; honey-like colour

- Typical beer styles: Belgian-Style Specialty Beers, such as Blonde, Bruin, Amber, Tripel, and Double

- Max. use in grain bill: up to 30%

We leave it to your wisdom & judgement as you are our valued customers and your feedback is very important for us to further excel in our endeavors! We are proud to share one of our creations in R&D with you.