The Benefits of Craft Beer & Beverages in Cans

Alfonso Posada

International Sales Director, Econocorp Inc.

ECONOCORP INC.

Randolph,

MA USA

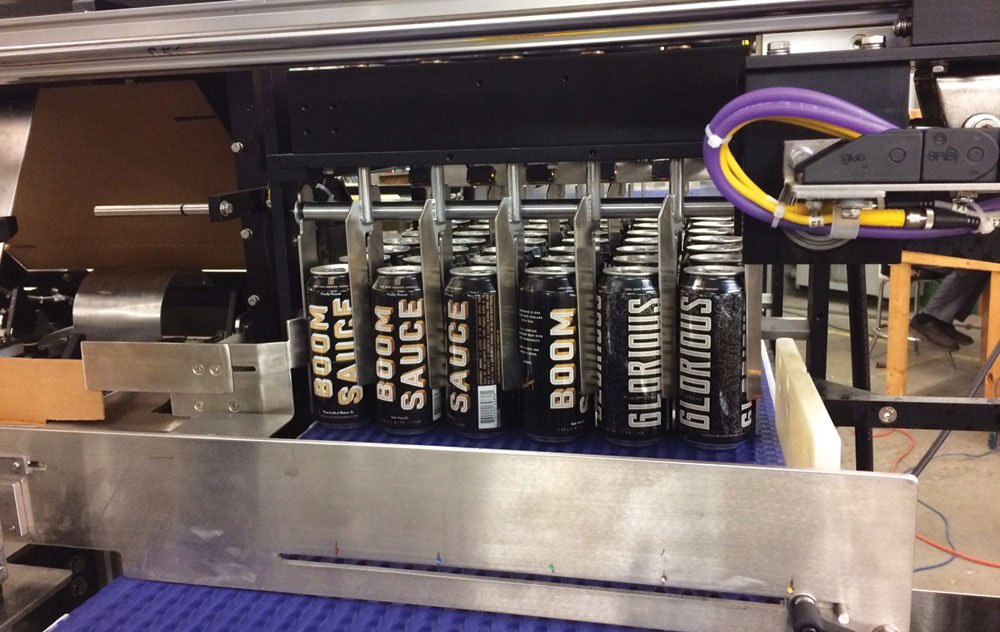

Econocorp Inc. is recognised as worldwide leaders in cartoning, tray formation and case packing for moderates and lower production volumes. Econocorp provides simple, compact and affordable packaging systems for cans within moderate production volumes up to 12,000 cans per hour.

Econocorp’s machinery specialized for beverage Cartoning for canning lines of:

- Craft Beer, Cider, Mixed drinks and wine

- Cold Coffee & Tea

- Energy Drinks, Hard Soda, Carbonated Soda

Our machines can be installed following canning lines manufactured by CFT Group, Krones, Cask, Comac, KHS, Cime Careddu, Palmer, ABE, Twin Monkey’s, Wild Goose or similar canning lines.

All equipment is created with simplicity in mind, using minimal parts in the design to reduce maintenance & repair costs. Our reliable packing material can increase output volume and decrease labour hours, creating a higher revenue for our clients. Our commitment to excellence has been a recipient of the Presidents E Star Awards, recognising our efforts in increasing imports & promoting exports in the USA. We have experienced sales partners in the Indian market whom can provide sales, service and parts.

CANS over BOTTLES – Advantages

Cans are the Best Vessel for Maintaining the Quality of Craft Beer

- Cans eliminate “light strike” (where a skunk-like flavour exists) in beer, as the can stops all light from reaching the beer

- Cans have a tighter seal than bottles, stopping any gases from entering, or leaving the vessel. Known as a hermetic seal, this helps reduce the rate at which the beer oxidizes

These two reasons alone mean the quality of the beer in cans is better

* Cans are Perfect for Outdoors

* Cans chill down faster than bottles.

- Aluminium is much thinner than glass, in fact as thin as a human hair. Anychanges in temperature are passed from the can exterior to its contents much more rapidly

- Cans have better thermal conductivity than glass. This means it requires less energy to cool cans, and as a result cans cool much faster. Think of a pot on the stove; if you’ve ever used a tin pot you would have noticed this heats up much faster in comparison to an iron pot, due to its better thermal conductivity

- Cans are also much lighter & better space maximization than bottles

- Two 330ml cans thrown in a pack weigh around 700 grams, while two 330ml bottles weigh in at 1,300 grams. That 600 gram difference means it will be much easier to climb hills when hiking without the extra weight burden

- Cans are much more efficient in terms of storage size. Two cans are roughly the same size as one bottle. If you want to save on space, go with the can!

- Cans mean you can double the amount of beer kept in the fridge at any one time – that’s space maximization right there!

Cans make it Easier and Cheaper for Breweries to Ship Large Amounts of Beer

Shipping beer, both in-country and overseas is a costly task. Any savings that can be achieved will result in the price of beer being cheaper.

Shipping in cans instead of glass bottles means savings can be achieved in a number of ways:

- More beer can be shipped at once. With two cans the equivalent of one glass bottle in size it means for every pallet of beer, twice as much can be transported, meaning the transport cost per unit goes down

- Beer in cans is lighter. As we mentioned previously, a beer can is approximately half the weight of a beer bottle. Where freight is charged on a weight basis, the comparative costs will be lower

- Cans keep the beer in better condition. With cans able to stop light strike and reduce oxidation, it means the brewer is able to sell their beers in the best condition possible

- Cans reduce breakages. Glass is a highly fragile product. Nobody likes crying over spilt beer from a glass breakage. Cans are a much more durable, alleviating any risk of breakage

Cans are better for Craft Breweries:

From a marketing and production perspective, cans are the ideal packaging format for craft breweries. There are four reasons for this:

- Cans have a greater surface area for branding. While the size of the bottle label is limited, the whole can is able to be branded. From a marketing perspective it means the can is better for communicating a brewery’s message

- The unit price of cans are cheaper. This provides another saving that can be passed onto the consumer

- Cans represent a more efficient packaging process. Provided that cans have been pre-printed, it means the canning process simply requires the can to be rinsed, filled with beer, and then a lid applied. In contrast bottles have the extra step of a label being applied at the end of the bottling cycle. This extra step takes more time, and increases the maintenance required of any packaging line

- “Silver Bullets” and wraps allow the creation of labels for limited release beers without significant expenditure. Printing cans can be expensive, with the minimum run of a printed can produced often large. “Silver Bullets” involve a brewery using an unbranded can and applying a label to the can at the end of the canning process. An example of a brewery that does this is Modus Operandi. They use a standardized can, with a label applied which clearly conveys what the beer is. A wrap meanwhile works in a similar way. It takes the unbranded can and applying a plastic wrap around the entire can. One brewery that does this is the Australian Brewery. Both Silver Bullets and wraps allow for easy customization of cans, making it a great approach for limited release beers

Cans are Perfect for Outdoor Venues

Whether it be stadiums, concerts, or sporting events, cans are the perfect packaging when glass is not permitted.

Cans are Better for the Environment

- Cans have a number of environmentally friendly strengths:

- Cans have a higher rate of recycling compared to glass. Metal cans are completely recyclable, and able to be recycled again and again without any performance loss. It is reported that the average can today contains around 70 percent recycled metal. A can that is recycled today can be back on shelves in as little as two months

- Recycling aluminium utilizes 95% less energy than creating aluminium from raw materials. This provides a great incentive for recycling cans

- Cans can be crushed smaller. Where a consumer has chosen not to recycling, there are still environmental benefits in that the vessel will take up less room in any garbage