Sustainable Brewing in the Time of COVID-19

Bars are closed, beer is going stale and people are sheltering nervously at home. Uncertainty about safety for both workers and customers makes it difficult to plan ahead. Brewers in India are now struggling with the effects of COVID-19. People are already talking about the end of the golden age of craft beer. While this may be an exaggeration – surely nobody who has tasted the delights of craft wishes to stop– it is clear that many breweries are suffering. Those who survive need to look ahead, but what does the future hold for craft beer?

According to Mae West “Too much of a good thing can be wonderful”. But is age of craft beer ending?

Sustainable New Priorities

While the lockdown won’t last forever, life won’t suddenly snap back to being exactly the same.

The COVID-19 epidemic could change consumer behavior in three ways. First, it is possible that increased focus on healthy behaviours could lead to more demand for lighter, lower-calorie beers. Secondly, money will be tight in many households, and affordability will become more important. Finally, there could be an increased emphasis on sustainability. This trend was already important, with ever more people becoming aware of the effects of pollution and climate change; now in lockdown, many city dwellers are breathing clean air and looking at blue skies for the first time in years.

Ideally, a post-COVID brew could offer it all. Is it possible to combine all three? Can you have affordability, lower calories, and better sustainability while still producing a great tasting beer? You can when you use the DuPont range of brewing enzymes.

What is an enzyme?

An enzyme is essentially a complex protein. Enzymes are natural products, present in all living things. They act as catalysts to speed up biochemical reactions. Enzymes are critical to our ability to digest food and produce energy that allows us to function every day. The action of an enzyme can increase the speed of a reaction speed by at least a million-fold. Enzymes are processing aids which they work only in the presence of a relevant substrate. Once the enzyme has done its work, it becomes just another protein.

Sustainable Brewing with DuPont enzymes

As breweries everywhere join the global climate fight and strive to brew more sustainably, enzymes are poised to play a crucial role[1]. Enzymes provide high productivity at low use rates – very small quantities can have large effects. This means the sustainability impact of brewing enzymes is high as they allow more to be done with less.

Sustainable means unmalted

Enzymes can enhance sustainability in brewing by making it possible to use un-malted raw materials such as unmalted barley, sorghum, cassava, corn and rice. Malt production consumes water and energy. DuPont enzymes such as ALPHALASE® AP4 and LAMINEX MaxFlow® 4G can help, allowing more sustainable brewing while increasing yields and reducing production costs.

Sustainable means Local Materials

Another way to improve the sustainability of your brew is by using local raw materials. This is a win-win as it reduces costs, lowers transportation emissions, and also supports local growers.

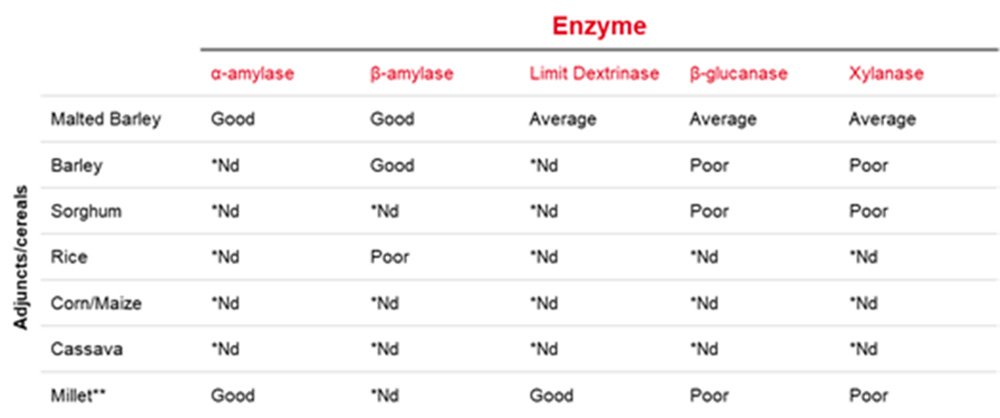

Different raw materials have varying heat capacities (Cp), different levels of viscosity-increasing soluble β-glucans and arabinoxylans,and contain different levels of enzymes.

Our team of experts can help find the right combination of enzymes to work with every starch source, so every brewer can find a way to brew sustainable using local ingredients.

Sustainable means lower energy consumption

LAMINEX® MaxFlow 4G is popular in breweries for its excellent performance as a filtration aid. The highly specific xylanases and ß-glucanases reduce wort viscosity, improve mash separation and beer filtration – making the process easier and faster, without changing the character of the beer produced.

While the cost savings due to improved yield and higher throughput are self-evident, DuPont has also found that significant energy savings can be achieved using LAMINEX® MaxFlow 4G. The Energy and Climate Change Potential (CCP) savings when using this enzyme solution are 45 times greater than the energy used in their production.

LAMINEX® MaxFlow 4G can potentially be used in the entire EU beer market where exogenous enzymes are allowed, with great potential environmental benefits (Figure 1). With approximately 400 Mhl beer produced annually in the EU, this is not just a drop in the ocean.

At full market penetration, the potential water saved using LAMINEX® MaxFlow 4G is equal to over 241 Olympic sized swimming pools on a life cycle assessment (LCA) basis. The greenhouse gas emissions saved are equivalent to the installation of 128 wind turbines. The land saved from improved barley yields is equivalent to 82 average-sized farms in Germany or nearly 6700 football pitches.

Sustainable means collaborating

Together with Briggs of Burton, DuPont has developed a new Mashing Energy Calculator[2. By simulating changes in levels of raw materials and corresponding mashing diagrams, it evaluates the potential impact the use of different materials and enzymes can have on energy and water consumption. Let’s work together for your next sustainable brew?

Sustainable means a luxurious light beer

Brut IPA, a beer reminiscent of fine champagne represents a new trend in brewing, taking reduced dextrin beers from diet to delicious. This tasty reduced brew is not only good for the waistline but is also light on the wallet and has a lower environmental footprint. First invented in 2018 in San Francisco, Brut IPA is a lighter, drier, effervescent beer with a clear golden colour. Brut IPA is possible due to the use of enzymes which break down more of the residual starch found in beer. Long unfermentable dextrin chains are chopped into smaller units which can be more easily converted into alcohol and carbon dioxide. This allows brewers to get more from less as a larger proportion of dextrin is converted into alcohol, flavour and bubbles.

To reduce calories, enzymes breakdown more of the residual starch found in beer. Basically, long, unfermentable dextrin chains are chopped into smaller units which can then be easily fermented into alcohol and carbon dioxide. So more for less, as more of the dextrin is converted into alcohol, flavour and carbon dioxide.

Many breweries in India are already using DuPont Enzymes such as the AMYLEX® and DIAZYME® ranges to brew Brut IPA. Now could be the time for a new, highly attenuated, low sugar beer with just a twist of flavour. Perhaps we could call this alternative Brut lager?

There is only one question. Just how do you brew it?

The Brut Lager is drier and lower in calories than prototype lagers with the same alcohol level. If you want to brew the ultimate Brut Lager or maybe name it Brut Blond, you’ll need to first select the right yeast strain and choose the perfect mixture of the grist with or without adjuncts. After that, there are 3 important points to keep in mind.

- To get a drier beer, you’ll need a higher proportion of glucose or maltose in the wort. To create this, you’re going to need help from some handy enzymes known as exogenous alpha-amylases & glucoamylases. These enzymes efficiently liquefy the starch in the grist, making it easier to break down into the fermentable sugars you need. Different raw materials contain widely varying natural levels of alpha-amylases, and with some grain combinations, you’ll need to add extra. Our AMYLEX® and DIAZYME® ranges of enzymes can help you here. To produce the ultimate dry lager, you need to use a slightly longer saccharification regime, allowing for maximum conversion of starch into simple sugars. Adding exogenous glucoamylases at this stage allows you to truly get the most out of your grist. The more you add, the faster the process.

- Another important factor is the target for the Real Degree of Fermentation (RDF). Also known as attenuation, this refers to the level of sugar in the wort which has been fermented into alcohol. The higher the level of RDF, the drier the beer. Even when using 100% malted barley, you will need extra enzymatic help to increase the RDF. The natural enzyme in the malted barley is deactivated when mashing at high temperatures. Because of this, regular beers typically have a maximum fermentability of less than 70-72% RDF.

A lower RDF means the final beer will contain more starch as the longer dextrin chains won’t be broken down. This gives regular lagers more body and mouthfeel, as well as a potentially sweeter taste. If you want to brew a truly dry beer, we recommend you aim for at least 79% RDF. With our new solution, DIAZYME® 87, you will be able to reach as high as 87% RDF!

- The DuPont DIAZYME® range of enzymes makes it easy for you to convert more starch into glucose and/or maltose setting you on the path to a deliciously Brut lager.

Brewing the Ultimate Brut Lager

An alternative way to produce a light beer is by adding the glucoamylase enzyme during fermentation. If you go down this path it’s important not to get these beers mixed with regular beers as this enzyme is still active. To avoid damaging normal non-dry beers, the enzyme will need to be inactivated using flash pasteurisation. Talk to us to understand which method of light beer brewing is right for you.

Do you aspire to brew the ultimate Brut lager? Or perhaps you want to experiment with other interesting drier beer styles. Why not Brut Wheat? Brut Saison? Brut Porter? Your imagination is the only limit. Whichever way you choose to brew your light beer, our application specialists are here to help. Our team of brewing experts can advise on how to use and dose our enzymes. Talk to us and get started on a Brut lager of your own.

Sustainable means brewing uniquely

At DuPont Brewing, we know that every brewer is different and has unique challenges and plans. We are continuously looking for ways to support breweries and help brewers achieve their goals. Our comprehensive range of specialist brewing enzymes can help to lower costs, improve sustainability and even produce delicious lower-calorie beers.

Authored by:

Jaydeep Chatterjee and Jens Eiken,

DuPont Nutrition and Biosciences

Sources:

[3] http://biosciences.dupont.com/solutions/food-and-beverages/brewing-enzymes/brewing-calculator/