Reduce Energy Dependence In Brewing

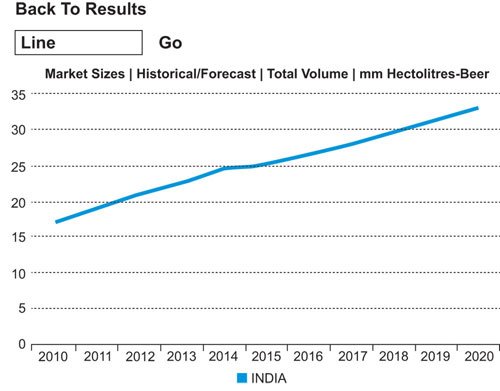

The brewing market in India is dynamic and growing, creating countless new opportunities for brewers. However, brewing in the country can be challenging due to inconsistent energy supply. Power losses in transmission and distribution networks across India average around 25 percent, and in some areas can reach 50 percent. This leads to disruptions, which have a negative impact on the long stabilization required during the brewing process. DSM brewer master for India, Siaw Yion-Miaw at DSM Food specialists shares the solution.

Challenges in beer stabilization

For the very important beer stabilization step, the unreliable energy supply can hamper the process and push production costs up. This poses a challenge for brewers who are very focused on first time right stabilization and cost efficient production, as consumers are sensitive to price and beer quality.

In order to stabilize beer using conventional stabilizing methods, the beer needs to be cooled to below zero degrees Celsius. Stabilization incurs costs including capex investments and maintenance to keep a large volume of beer at an exact temperature. Process utilities such as water and detergent for equipment cleaning are also required and brewers may need to have an extra cooling medium such as ammonia or glycol on site. In India, cooling can be even more challenging due to the warm climate and as a result of unreliable energy supply, breweries have to invest in additional capital expenditure for expensive power generators to keep production running. Relying on generators also adds a risk to the production continuity of the brewery.

Remove the energy intensive cooling step

The removal of the cooling step in stabilization helps to reduce production costs and energy reliance and DSM has developed a patented solution that does just that. Brewers Clarex enables stabilization at temperatures up to 7°C. This makes the cooling step unnecessary and allows brew masters to reduce the amount of energy used by up to 6%, resulting in lower production costs and a reduced environmental footprint.

Reduce stabilization time from weeks to days

In addition to the energy reduction benefits, this lean brewing innovation reduces the stabilization process from weeks to days, accelerating time to market without requiring large investments for production expansion. In fact, several breweries in Europe and South East Asia, which belong to a global brewery groups, have been able to shorten their stabilization time from days to less than an hour, thanks to the application of Brewers Clarex.

Easy to apply

Brewers Clarex is a liquid, allowing for precise dosing and simplifying the beer filtering process, without the need for handling and rinsing of stabilization powder. It can be used with all kinds of malts and other raw materials. No large equipment is needed to start using Brewers Clarex. In general, only a small dosing pump is installed and Brewers Clarex can be simply added in small quantities to the fermentation vessel at the start of fermentation. It does not need to be dosed proportionally to the cold wort flow into the fermentation vessel, but can be dosed at any time while filling the vessels. Proper mixing is ensured by the normal yeast fermentation process. Because Brewers Clarex doesn’t have to be filtered out and rinsed, beer loss is also reduced. Furthermore, it has no impact on beer (taste or foam) quality. Apart from the fact that Brewers Clarex is so easy to use, DSM’s customers have expressed that they are pleased that they no longer have to handle powdered products in the stabilization process, which saves them handling time and improves their efficiency.

Simple and efficient capacity expansion

Furthermore, breweries in India wanting to expand their production can do so easily and with less cost using Brewers Clarex, as no extra Capex investment is needed for expensive cooling facilities and an extra fermentation tank. Additionally, breweries can remarkably shorten their stabilization time and brew more efficiently.

Support by regional DSM brew masters

DSM works hand-in-hand with leading breweries across the globe, providing support from teams of regional DSM brew masters and by our Innovation Centers in the Netherlands and China and global application laboratories.