Enabling Breweries to Experiment Successfully with Raw Materials

Jaydeep Chatterjee

Sr. Application Specialist – Brewing, ASPAC & SA, DuPont

The Brewing Industry in India has seen a phenomenal ride in the past decade. With the emergence of micro and craft breweries, beer lovers now have a chance to enjoy different beer styles. A few years ago, this would have been unimaginable because India is predominantly a lager beer market and the presence of other beer styles were practically absent. Thanks to brewers and entrepreneurs who took the challenge and made it happen.

Currently, the largest selling style of beer in the micro and craft brewing segment is wheat beer, both German and Belgian styles. Following the trend, big players are coming up with wheat beers, and we can already see them in the shelves, with new brands getting launched every month.

So, we are not far from a time when wheat beer will be available over the counter in retail shops across India.

Does this mean that other beer styles will also see the same trend as wheat beer? Will micro and craft breweries lose the edge of beer styles they have crafted in India? Will India see the craft beer revolution as seen in USA? Only time will tell. However, some evolution will take place. As the saying goes, “Change is the only constant”

Beer lovers in India are experimenting tasting new beer styles – some successful some less successful. At the same time, they have a high expectation of flavour, taste, sustainability and quality. They are also informed about FSSAI regulations. This has created both challenges and opportunities for the brewers to keep their customers engaged and loyal.

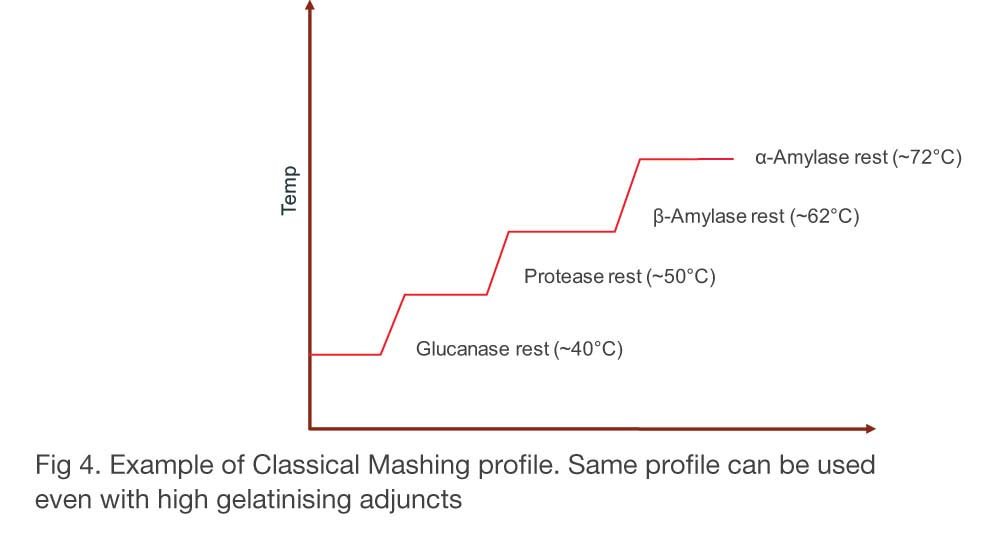

Breweries have started experimenting in beer styles, raw material choices and processing. Unmalted cereals which have rarely been tried and tested in India are now being used. These include raw wheat, sorghum, ragi, rye, raw barley, millets (apart from corn and rice). Lagers and Ales brewed out of these cereals have received good consumer acceptance. Possibility of mixing different cereals in a single mash vessel has opened new dimensions in developing interesting tastes and flavors. These cereals are sourced from local farmers and hence, the supply chain is more sustainable with added social responsibility to reach out to farmers. DuPont brewing team is continuously innovating enzymatic solutions to help breweries achieve United Nations Sustainable Development Goals (Fig 1).

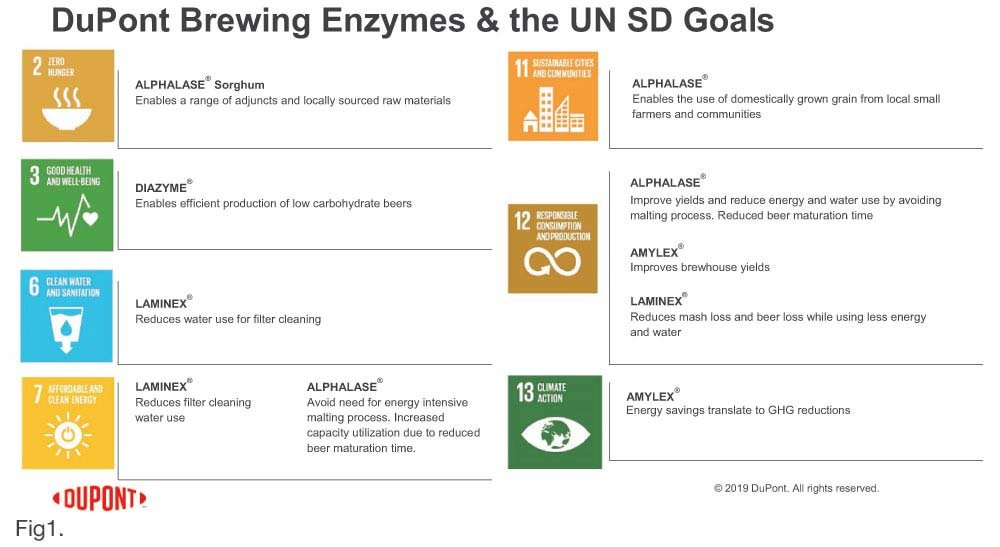

Processing these cereals has its own challenges in brewing especially with high gelatinization temperatures to process these cereals (Fig 2). DuPont brewing team is working with brewers across the globe to address these challenges, providing them technical expertise from a team of experienced master brewers.

Common gelatinization temperature ranges of cereals/adjuncts:

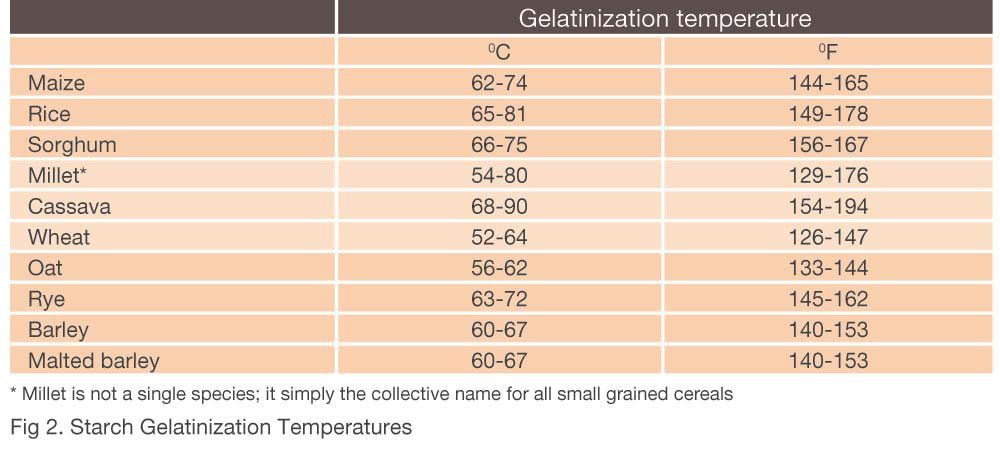

A cereal cooking step is traditionally considered to be required to bring starch and essential nutrients from these cereals to solution before being broken down to simpler sugars (Fig 3). However, the traditional way to cook these cereals with malt is not that effective due to the complexity of the composition of the cereals and deactivation of malt enzymes at elevated temperatures. Many times, the mash becomes very viscous and cannot be filtered. Sometimes the same cereal differs in composition and quality when sourced from different regions, even different farmers, and hence the chance of inconsistent beer quality is very high.

DuPont brewing team has developed customized solutions to process these raw materials with cutting edge innovative solutions suitable for Indian conditions.

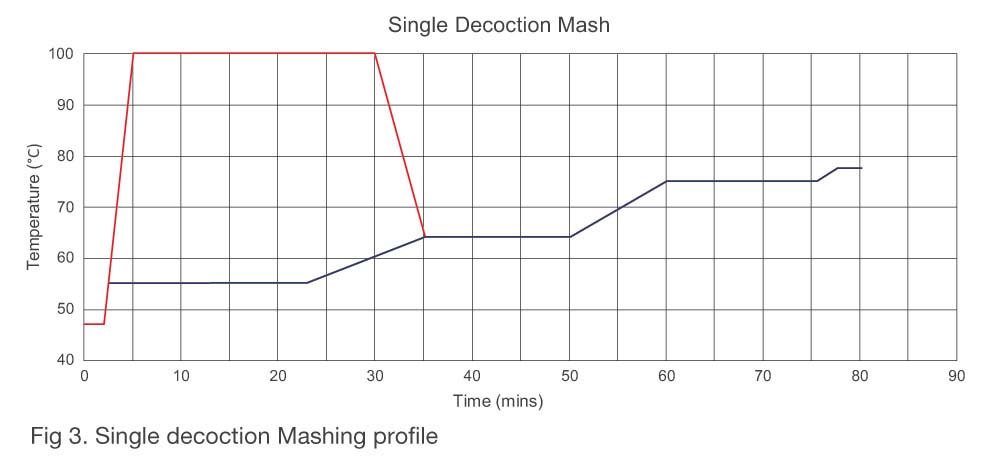

With the use of DuPont’s exogenous enzymes, the need to cook these cereals in cooking vessels has been eliminated. The risk of extract loss, so far, a concern for brewers, has been averted. Breweries which does not have a cereal cooker are now taking the benefit of using these raw materials and making innovative beer brands. Therefore, only a single vessel is required to mash the brews out of these cereals to make different beer styles. Apart from these, brewers are now empowered to follow classical brewing temperature profile in Mash Tun without the requirement of boiling the cereals (Fig 4.)

Viscosity of the mash is no longer a problem, thus eliminating challenges in filtration.

With improved mashing techniques, the staling problem in beer has been reduced. This has improved flavor acceptance of these beers. Brewers, who don’t have a cereal cooker and a mash filter, are taking advantage of this new concept without any capital investment.

There is a trend to brew beers in India with isothermal mashing process as followed in the UK. This requires well modified malted cereals. However not all enzymes are available in all cereals, even if they are malted. With DuPont brewing solution, it is now possible to brew beer with isothermal mashing even with unmalted cereals.

With new innovations coming from DuPont in the future, we can expect more enablers for brewers to brew uniquely to satisfy beer lovers in this dynamic brewing world.