Discover the World of Malts

Viking Malts

Timo Huttunen

Director, Special Malts, Viking Malts

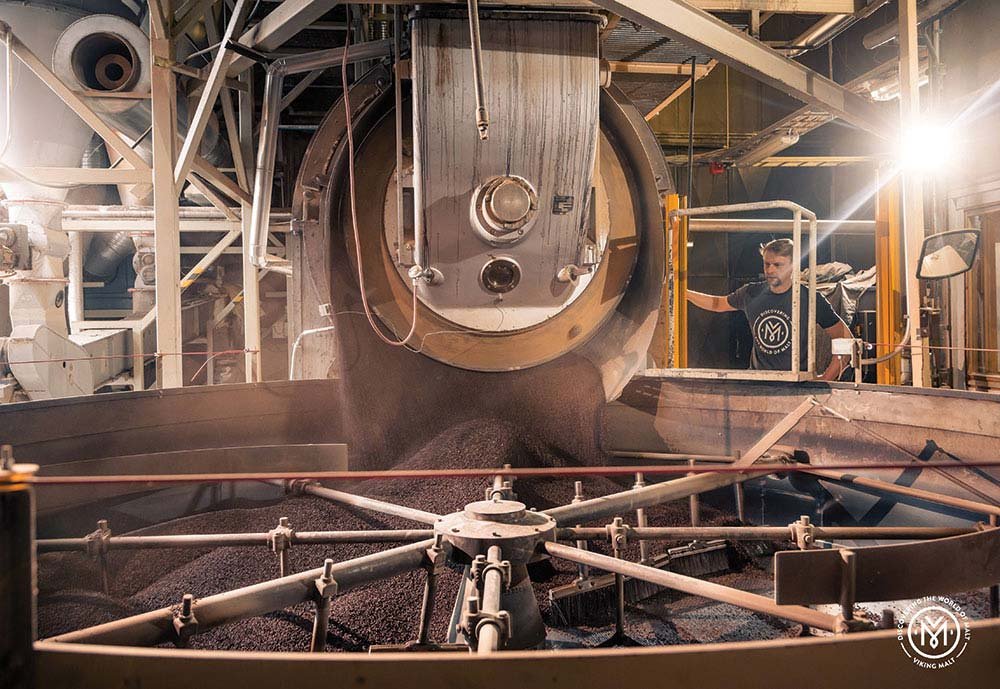

Viking Malts is one of the world’s leading malting companies of speciality malts. Sourced from the pure fields of Northern Europe, their mission is to help devoted brewers around the globe to make beers that people tell stories about. Pioneers in malting, backed by maltsters who are well versed in the long traditions of brewing, they constantly experiment with new methods as well as rediscovering old ones.

Viking Malt’s six malthouses are located in Halmstad, Sweden; Vordingbrog, Denmark; Lahti, Finland; Panevėžys, Lithuania and Sierpc & Strzegom in Poland. Located close to the farming areas, ensuring the distance from the field to the malthouse is short. Thus, assured of the quality and origins of each batch of malt.

All Viking Malts products are available in India through their business partner representative BrewNation which stock the entire range of Viking malts in India in several warehouses.

Viking malt® is an old and established brand. How do you take this legacy into the future?

Viking Malts history dates back to 1883, when Oy Lahden Polttimo Ab was founded in Lahti, Finland. The year 1934 saw the birth of our commercial malt production in Finland. Polttimo Oy began to internationalize in the 1970s through corporate partnerships. Nord-Malt was established in Söderhamn, Sweden, alongside Svenska Malt AB in Halmstad. Litmalt in Lithuania joined the company in 1997.

Viking Malts history dates back to 1883, when Oy Lahden Polttimo Ab was founded in Lahti, Finland. The year 1934 saw the birth of our commercial malt production in Finland. Polttimo Oy began to internationalize in the 1970s through corporate partnerships. Nord-Malt was established in Söderhamn, Sweden, alongside Svenska Malt AB in Halmstad. Litmalt in Lithuania joined the company in 1997.

In 2016 Viking Malt joined forces with Danish Malting Group. DMG was founded in 1996 and it is the largest malting house in Denmark. In Poland the oldest DMG maltings in Strzegom dates back to 1897 and the DMG Polska maltings in Sierpc were constructed in 1975. With a Nordic & modern twist, the new Viking Malt is today the biggest malting company in the Baltic Rim area and 5th largest in Europe with close to 600 k tn malting capacity/a. In special malts we are the market leader globally.

How do you approach the business side of malting?

We target home markets with direct business model to all brewing customers, at export markets through strong, selected local distributors. With a Viking appropriate statement of “Discovering the World of Malt” the diversity and selection of malts is high and protein and dmsp levels are on average lower than similar domestic malts. Viking only sources non-GMO modified barley from local farmers located close to their six malting houses. Additionally, the cold winters of Northern Europe provide a natural pest reduction, greatly lessening the need to use chemical pesticides. At Viking Malts our approach is four fold-

- Curiosity: We are genuinely passionate about beer & how malt can play an important role in its history. Our maltsters are well versed in the long traditions of brewing. We are pioneers is malting & constantly experiment with new methods, as well as rediscovering old ones

- Character: We produce special malts for special beers. As much as a beer has to have character so does the malt. We work in direct cooperation with our dedicated farmers; every grain can be traced back to where it came from

- Craftsmanship: The world of malts is full of fascinating beers & the people behind it. Our maltsters & farmers offer you malts with a personal touch: New varieties, tailored recipes or signature malts

- Cooperation: We are a big but small malting company & we work in cooperation with our clients to understand their requirements from malt. And to understand what they might be looking for, before they even realise they might need it.

- In your view, what are the secrets of good beer making? Without going into the technical details; a brewer needs to have good overall understanding of the whole process and have a clear picture what he / she wants. Good beer might be a matter of personal taste, but the malt used in it must always be high-quality. We do everything to ensure the quality of our malts.

- We select our raw materials with care and monitor production closely

- The operations of our malthouses are based on local malting barley which enables easy traceability

- According to our environmental policy we use only selected agricultural raw materials, and we process them efficiently and profitably

- Efficient supply chains gives us improved control over variety development, farmer cooperation and grain quality

What are the process steps required to turning out top-quality products?

Malting is the work of professionals. Ultimately, our skilled maltsters are the guarantee of our quality. We invest in their knowledge & education constantly.

We operate according to integrated management system Quality (ISO 9001) which includes:

- Food Safety (ISO 22000)

- Environment (ISO 14000) and

- Energy (ISO 50000 Denmark only)

We also have internal and external audits to evaluate our operations, and we are certified in all the mentioned management systems. We are also developing our operations towards Health and Safety Management system (ISO 45000).

Talking about quality, how do you see the positioning of the Viking Malt® identity in the industry?

We see ourselves as constant high-quality maltster that has the whole process under own control from barley fields to malt deliveries. Our aim is to help devoted brewers around the globe to make beers that help people tell stories. the new Viking Malt is today the biggest malting company in the Baltic Rim area and 5th largest in Europe with close to 600 k tn malting capacity/a. In special malts we are the market leader globally.

What is your quality issue resolution process?

To ensure sustainable procurement with respect to ethical, social and environmental issues, the Supplier Code of Conduct summarizes the requirements to which Viking Malt Group is committed and to which Viking Malt requires its suppliers to commit in order to conduct business with Viking Malt. Our overall goal is to encourage respect for Human and Labour Rights as well as Environmental protection and Business ethics with our suppliers of products and services.

The quality assurance at Viking Malt is based on operations, which are in line with ISO 9000 standard and supported with operations, which in turn fulfill ISO 22000 standard requirements in order to ensure the food safety issues. The basis for product quality is designed during the product development and production planning phase.

Are your raw materials sustainably sourced?

We operate with a natural raw material that varies from crop to crop, and with customers specifications that are complex and demanding. Climate change may increase risks related to product safety as well as quality. The success of a harvest depends on many things. Excellent growing conditions are vital in producing quality barley. Climate in particular has a profound effect on the crop. During the growing season, we continuously monitor changes in the environment and the development of the crop, as well as the status of the global malt market in order to ensure that we continue to produce high-quality malt for various purposes.

We operate with a natural raw material that varies from crop to crop, and with customers specifications that are complex and demanding. Climate change may increase risks related to product safety as well as quality. The success of a harvest depends on many things. Excellent growing conditions are vital in producing quality barley. Climate in particular has a profound effect on the crop. During the growing season, we continuously monitor changes in the environment and the development of the crop, as well as the status of the global malt market in order to ensure that we continue to produce high-quality malt for various purposes.

The northern nature offers us unique raw materials. Clean air, pure water and responsibly produced, high quality malting barley are essential for our products. That is why we want to take care of the nature that surrounds us in all our operations. That means using raw materials and energy efficiently, monitoring the environmental effects of our activities, and ensuring that our staff is well informed on environmental issues.

How does your company give back to the community? Are there any specific causes you are dedicated to supporting?

We follow requirements of current laws and official regulations, and continuously improve our environmental system and performance. We have identified our significant environmental aspects of our operations and established environmental objectives. Our long-term targets have been to reduce energy and water usage, and to increase environmental awareness.

We follow requirements of current laws and official regulations, and continuously improve our environmental system and performance. We have identified our significant environmental aspects of our operations and established environmental objectives. Our long-term targets have been to reduce energy and water usage, and to increase environmental awareness.

- To ensure sustainable procurement with respect to ethical, social and environmental issues, we have introduced a Supplier Code of Conduct that summarizes the requirements to which Viking Malt Group is committed

- We have signed Baltic Sea Action Group initiative. BSAG works to find solutions and right actors to restore the good ecological balance of the Baltic Sea. BSAG is foundation based in Finland

- Renewable energy in used in our sites in Finland, Sweden and Denmark. Only plants in Poland and Lithuania still have natural gas and coal as energy source

- To reduce CO2 emissions Viking Malt promotes introduction of high-yielding malting barley varieties in close cooperation with breeding companies and customers

- We are engaged in projects aiming to reduce water usage in the production process

- We are involved in different Malting Barley Cultivation Programs in our local countries, with an aim to promote malting barley growing and educate farmers how to be more efficient and environmentally sound with their farming practice. For example, Precision Agriculture techniques enables farmers to increase production efficiency while minimizing CO2 emissions

What keeps Viking Malt® ahead of the competition?

Our strategy is to ensure profitable growth with sustainable operations, an adaptive product portfolio and superior customer service. We’re passionate about our malts, people & our partners, and we have the highest regards for clients & consumers. We focus on the following with utmost precision

- Quality

- Research & Development

- Sustainability

- Code of ConductLatest Addition to the Market: Viking Pilsner Zero malt:

- Viking Pilsner Zero Malt is made from 2-row null-LOX spring barley. As a special feature in null-LOX varieties is that Lipoxygenase activity is zero, affecting positively on flavor stability of beer. barley. Steeping and germination conditions are chosen to promote even germination and homogenous modification. The final air-on temperature in kilning is typically 80-85°C. Pilsner malt flavour is usually described as malty, slighty nutty and sweet

About BrewNation:

In March 2016, BrewNation was created, and dedicated to supply products and provide technical support to the brewing segment. It has everything a brewer can dream of – finest equipment and raw materials like YCH hops, Bavarian malts, yeast, herbs, spices, oak barrels for ageing beer, dispensing towers, kegerators, glassware, innovative tools like gas blenders, nitro generators and more. It’s a single point contact for all things one needs for setting up a brewery. Ankit Sethi, an engineer, maltster, distiller, brewer and the founder of BrewNation intiated ‘Brew Talks’ an interactive brewing & communicative session, creating a forum for the Indian craft brewing community. BrewNation also stocks Viking Malts, Pilsner Zero Malt, along with all Viking Malts products which are available in India.