Brewing Process Hygiene and its Control in Beer Production

Bijay Bahadur

Bijay Bahadur has more than 29 years of experience in Indian and multinational breweries, IMFL bottling plants, brewery green-field and brown-field projects and factory operations such as maintenance, production, environment health and safety, and project management. He is also the author of Brewing – A Practical Approach, which is for practicing brewers, students pursuing careers in Food Technology, Biochemical Engineering or Brewing Science, and consultants who provide technical advice to breweries and entrepreneurs. He is a practicing brewer and specializes in the manufacturing of beer, including the formulation of recipes, overseeing new technical developments, implementing standard operating procedures, planning budgets, warehousing and inventory control, and liaising with Quality Assurance Department (QAD). He is a lifetime member and elected as FELLOW of the Institution of Engineers (India), the Indian Institute of Chemical Engineers and the Association of Food Scientists & Technologists (India). He has been authorized to use the style and title of Chartered Engineer (India) by the Institution of Engineers (India) as well as been elected as Professional Engineer by Engineering Council of India, New Delhi for a period of five years.

Brewing process hygiene plays a key role in the production of high quality beer. Knowledge of microorganisms found in the brewery environment and the control of microbial fouling are both essential in the prevention of microbial spoilage of beer. Beer is generally regarded as safe in terms of food-borne illnesses, due to the belief that pathogens are not able to grow in beer. The biological stability of modern brewery products is also very good, with best before dates ranging from 6 to 12 months or more from production even though hygiene is still considered so important in the brewing industry.

The brewing process itself is prone to growth of microorganisms because of the nutrient-rich environment of wort and the additional growth factors produced by the brewing yeast. The comparatively long production run from wort boiling to beer packaging, with batch fermentations of up to 15 to 20 days, gives plenty of time for unwanted microorganisms to develop if they are given the opportunity. Thus, at any cost, the breweries avoid the risk that the image of a beer would suffer because of quality losses due to microbiological problems in the process. The hygiene of vessels, machines and other process surfaces crucially affects the quality of the finished beer. To ensure high quality, reliable detection of microorganism that could have a detrimental effect on the beer is essential as early as possible.

It is important to specifically identify the problem-causing microbe in order to be able to trace the source of contamination in the process. A required task in process hygiene assessment is the detection of low numbers of microorganisms after sanitation – especially because the surviving cells are often stressed and their metabolic activity is low. The objective of brewery process hygiene is to ensure product quality and minimise contamination risks. The optimisation of cleaning procedures is important to improve economic efficiency and to reduce damage to the environment. Rapid and reliable methods must be used for hygiene control.

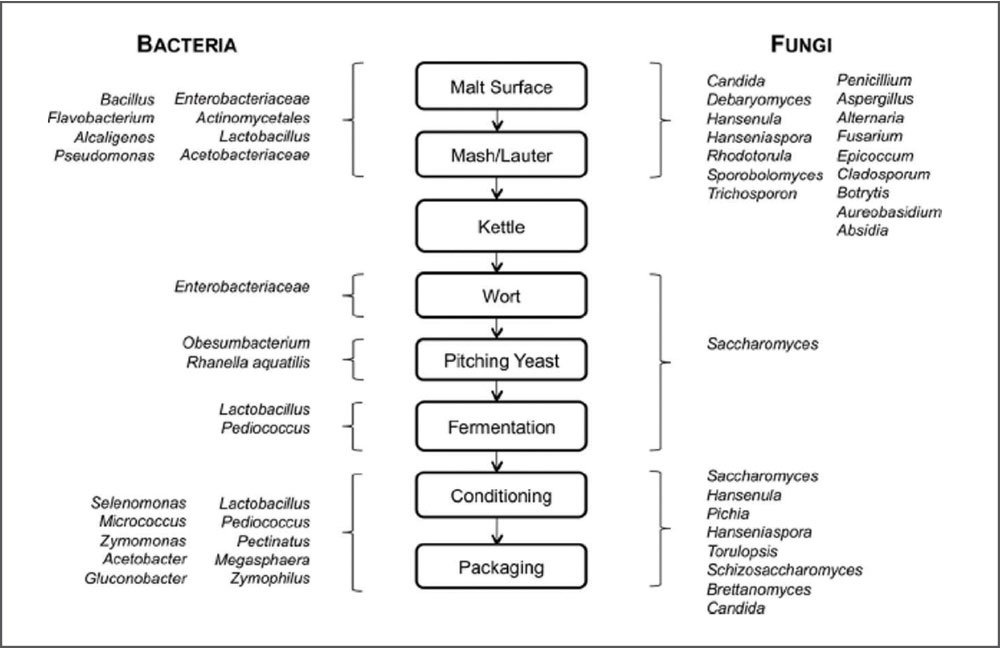

Microorganisms Related with Brewing Process

The presence of inhibitors such as hop compounds, alcohol, carbon dioxide and sulphur dioxide as well as the shortage of nutrients and oxygen and the low pH all make the beer resistant to microbial contamination. Moreover, processes such as filtration, storage at low temperatures (lagering) and pasteurisation reduce contamination. The special environment in the brewing process restricts the range of microorganisms likely to be encountered to relatively few species. Although the contaminants found may cause quality defects, pathogens will not grow in the standard finished beer.

Microorganisms encountered in the brewery are divided into 5 categories depending on their spoilage characters:

1. Absolute:

Tolerate the selective environment in beer. These organisms grow in beer without long adaption and as a result cause off flavours and turbidity or precipitates.

2. Potential beer spoilage organisms:

Normally do not grow in beer. However, beers with high pH, low hop concentration, low degree of fermentation, low alcohol content or high oxygen content may be susceptible. The category of potential beer spoilers also includes organisms which can adapt to grow in beer after long exposure times.

3. Indirect beer spoilage organisms:

Do not grow in finished beer but they may start to grow at some stages of the process, causing off flavours in the final beer. Typically, they occur in the pitching yeast or in the beginning of fermentation, causing quality defects that must be avoided by blending.

4. Indicator organisms:

Do not cause spoilage but they appear as a consequence of insufficient cleaning or errors in the brewing process. Their presence is often associated with the occurrence of beer spoilage organisms.

5. Latent organisms:

Which are sporadically encountered in the brewing process and which in some cases even can survive the different process stage and be isolated from the finished beer. Usually members of this group are common organisms in soil and water and their presence in the brewery is often due to contaminated process water or to construction work inside the brewery. However, if they are found quite frequently, shows a sign of poor hygiene.

Sources of Contamination

Contaminations in the brewery are usually divided into primary contaminations (brewing) and secondary contaminations (bottling). About 50% of the microbiological problems can be attributed to secondary contaminations, but the consequences of primary contaminations can be more comprehensive and disastrous. Absolute beer spoilage organisms may appear at any stage of the process, whereas indirect spoilage organisms are mainly primary contaminants. The spoilage character of a particular organism depends on where in the process it is found. After filtration, the brewing yeast is also be regarded as a contaminant.

Primary contaminations:

Originating from the yeast, wort, fermentation, maturation (lagering). Soiled equipment is a significant source of contamination in brews pitched with pure culture yeast.

The pitching yeast, dirty return bottles and rest beer are the most important sources of contamination. Weak points in the brewery which are sources of contamination include measuring instruments such as thermometers and pressure gauges, valves, dead ends, gas pipes (due to condensate) and worn floor surfaces. Contamination may also occur when hot wort is cooled in plate heat exchangers, as a result of leaking plates, inadequate cleaning of the plates or wort aeration. Contaminated filter powder or dirty filters or additives such as finings may also cause contamination.

Secondary contaminations:

Originating from bottling, canning or kegging where the breweries are not using tunnel pasteurisation. Thus, all points with direct or indirect contact with cleaned or with filled unsealed bottles are possible sources of contamination. Most common causes of secondary contaminations are: the sealer/crowner, the filler, the bottle inspector, the bottle washer due to dripping water and the environment close to the filler and sealer.

Airborne contamination of beer can occur in the bottling department during transport of open bottles from the bottle washer to the filler and until the bottle has been sealed/crowned.

High numbers of beer-spoilage bacteria in the air have been associated with problems of microbiological spoilage of bottled beer. The highest numbers of potentially beer-spoiling bacteria are mainly encountered in the air close to the filler and crowner.

Strategies for Control of Contaminations

Control of microbial spoilage of beer is best achieved by eliminating the sources of contamination. Traditional control strategies in the beverage industry include:

- Increasing the resistance of the beer to microbial attack by pH adjustment, addition of antimicrobial compounds, reducing water activity, increasing osmotic pressure etc.

- Processes aimed at reducing the microbial load such as filtration, the use of elevated temperatures (vigorous boiling, pasteurisation etc) and storage at reduced temperatures.

- Hygienic design of equipment used for brewing and bottling including choice of suitable materials and elimination of minimisation of dead spaces and rough surfaces.

- Physical separation of high care areas in which critical operations are undertaken and barrier technologies are practised to prevent the entry of microorganisms from raw materials, people, air.

- Effective regular cleaning and disinfection of equipment and facilities.

Resistance to Microbial Spoilage of Beer

The type of beer determines its ability to resist microbial spoilage. The most resistant beers are strong beers and beers with a pH below 4.3. These beers can be spoiled only by certain strains of absolute beer spoiling wild yeasts. Also, quite resistant are all malt beers with pH 4.4 – 4.6 and beers with a high hop content. Most prone to spoilage are beers with low acidity. Low alcohol beers, beers with added sugar or a high fermentable rest extract and beers with a low carbon dioxide concentration.

Processes for Reduction of Microorganisms

Processes used for removal of the pitching yeast or reduction of contaminating microorganisms in brewing of beer are summarised in Table 1.

[table id=12 /]

Pitching yeast is one of the most important contamination routes in the brewery and therefore, it is essential to keep the yeast free of contaminating organisms. Washing the pitching yeast is not regarded as good practice because of the negative effect of acid washing on the yeast viability. Therefore, it is not advisable to do yeast washing rather rely on careful yeast handling and efficient sanitation of equipment.

Filtration is used to remove the yeast and possible contaminants after fermentation. The filtration process is generally carried out stepwise. First yeast, haze particles and majority of bacteria are removed in the clarification step in which kieselhuhr (diatomaceous earth) filtration is applied. In a second filtration step, filter sheets, filter cartridge can be used with the purpose of removing any possible residual microorganisms from the beer.

Pasteurisation is used to eliminate the beer spoilage organisms in final beer. The treatment is dependent on the time and temperature used as expressed as pasteurisation units (PU).

‘Aseptic packaging’ or strict ensuring of hygiene during filling is applied. The frequency of disinfectant spraying at filler and crowner is important: disinfecting at the beginning and at the end of production is not sufficient to reduce the number of beer spoilage organisms in the air.

The filling operation can also be carried out in aseptic rooms or in an aseptic envelope. In these applications, the incoming air is HEPA-filter (high efficiency particulate air filter) and the air pressure in the room is higher than outside. Special clothing is used in the filling area and all the packaging materials is sanitised by UV, hot water or a disinfectant. The room temperature should be maintained below 20°C with proper ventilation. Machines are designed and modified to make them more easily cleanable.

Hygienic Design

Hygienic design practices are important aspects required for controlling and minimization of contaminations in brewery equipments such as tanks, pipelines, joints and other related accessories. Design mainly include suitable choice of equipment, materials and accessories, correct construction, process layout and process automation. The hygienic design should be done so that all the surfaces in contact with the beverage are easy to clean. Generally, all the beer-contact surfaces should be smooth; pits, crevices, sharp edges and dead ends should be avoided and all equipments and pipelines should be self-draining.

Valves cause a significant risk of contamination in the brewing process and the risk increases with each valve installed in the brewing process lines. Plug valves and traditional ball valves are not suitable for CIP. There should be as few seals in a valve as possible and the maximum compressibility of the sealing material should not be exceeded during processing, cleaning or thermal treatment.

In the filling room, constructions should be open to facilitate cleaning and should not allow any liquid to remain on surfaces. Drop plates should be avoided wherever possible since they collect dirt. Cable installation should be avoided in the wet area wherever possible or they should be in closed pipes with access from below. Drains must be correctly sized and placed in order to avoid any water and organic residues and floor coverings must be chosen so that they can be effectively cleaned and maintained.

Because the air is one of the possible contamination route in the beer production, it is recommended to ensure good quality air especially in the packaging department. The location of the machines has an impact on the microbiological quality of the air. The bottle washer should preferably be located at some distance from the filler because of the generation of heat and humidity, and the same applies for the labelling machine because of the organic load caused by glue.

Cleaning and Disinfection

The role of cleaning and disinfection for the breweries (small or large) has grown immensely. Chemical cleaners have been found to be more effective in eliminating attached bacteria from the surfaces than disinfectants.

Cleaning-in-place (CIP) procedures are employed in closed processing lines of the brewing process. However, the limitation of CIP procedures is the accumulation of microorganisms on the equipment surfaces. The mechanical input in cleaning has shown to be critical in removing soils/microbes. Mechanical force can be achieved by turbulence flow in the pipelines and spray nozzles in the cylindrical tanks, but in practice there are places in the process where the mechanical action is low. Bacteria attached in pits and crevices are difficult to remove by cleaning agents because of poor chemical penetration and possibly also because of surface tension.

In breweries, acid-based detergents may be preferred for tank cleaning because of the following practical advantages:

- Acids are not affected by carbon dioxide and do not loose their cleaning efficiency when used on a recovery system

- They prevent carbon dioxide losses by allowing cleaning and sanitising to take place without the need to vent down tanks and they facilitate carbon dioxide to pressure cleaning

- There is less risk of tank collapse compared to the case of caustic soda reacting with carbon dioxide and due to the use of ambient temperatures

- They are efficient in removing and preventing beer stone and hard water deposits

- They are more cost effective than alkaline detergents because the high detergent losses due to carbonation of alkalis do not occur

- They are more effective in terms of water consumption since they are more quickly rinsed away

- They are energy efficient because hot cleaning is not necessary

The cleaning of open surfaces in the brewery, such as bottle inspectors, fillers and conveyor chains in the bottling hall, is usually performed using low-pressure foam systems or thin film cleaning. The use of hot solutions or strong chemicals is limited for safety reasons, but disinfectants also effective in cold conditions can be used to ensure the hygiene. It is recommended that foam cleaning and subsequent spraying with a disinfectant after every production day and regular basic cleaning including dismantling of components that are difficult to inspect visually. However, care must be taken to avoid transmission of spoilage organisms resulting from aerosols produced during pressure-cleaning.

Table 2. Typical CIP programmes for the brewery

[table id=13 /]

Table 3. Foam cleaning and disinfection programme

[table id=14 /]

The purpose of disinfection is to reduce the surface population of viable microorganisms after cleaning and to prevent microbial growth on surfaces during the interproduction time. Microorganisms that are exposed to the disinfection on beer processing surfaces are those remain after the cleaning stage and thus are likely to be surface attached.

In choosing disinfectants for use in brewery, the following characteristics are of importance.

- Effective against Gram – positive and Gram – negative bacteria and against yeasts

- Effective in the presence of proteins

- Effective at low temperatures

- Wetting ability

- CIP-suitability (low foam formation, compatibility with carbon dioxide, concentration measurable by conductibility, reusable/not easily decomposable).

- Environmental aspects (easily rinseable, readily biodegradable).

- Economy (effective at low concentrations, reusable, easily rinseable).

- Health aspects – safe to use.

- Product compatibility – no adverse effects on the product

When heat is used for disinfection, moist heat is far more effective than dry heat. In the process, such dry condition may occur if microorganisms are located between metal surfaces, between a seal and a stainless-steel surface or in microscopically small cracks in the process materials.

Assessment of Process Hygiene

The total quality management (TQM) can be divided into 3 processes:

1. Quality Control

2. Quality Assurance

3. Quality improvement

The Hazard Analysis Critical Control Point (HACCP) system is a safety tool and it can be incorporated into TQM programmes for the following reasons:

- To improve the efficacy of the operations and quality of the products

- To satisfy the requirement of the customers and purchasers

- To prove a due diligence defence in legal actions

- To keep up with the competitors

The HACCP system replaces traditional end-point quality control with a more systematic approach based on preventive quality assurance. The health risk involved in beer production are mostly of chemical or physical origin due to the fact that pathogens do not grow in beer. However, in addition to complying with legislation to assure consumer safety, a well-designed HACCP system can be used to manage and optimise the analysis of product quality parameters throughout the production process.

Conclusions

Biofilm formation may affect the performance of the brewing process and the quality of the final beer, thus causing economical losses.

Microorganisms involved in beer spoilage producing biofilm on stainless-steel in conditions resembling those of the brewing process. The organisms producing biofilm are stains of acetic acid bacteria, lactic acid bacteria, enterobacteria and yeasts. Microbial growth is observed on different surfaces used in process equipment, but environmental conditions strongly affects attachment and biofilm formation.

Process surface materials are found to differ in their susceptibility to biofilm formation. Biofilm is found to develop readily on stainless-steel, PTFE (polytetrafluoroethylene), EPDM (ethylene propylene diene monomer) and Viton. NBR (nitrile butadiene rubber) inhibited the growth of these organisms when new, but gradually lost this ability with increasing age.

Successful assessment of surface hygiene in the brewing process results in many beneficial impacts of economic and environmental value. Preventive measures based on accurate information on materials, process matrices and microorganisms are in most cases superior in ensuring process efficiency and product quality. In acute contamination situation, specific characterisation of the contaminant is needed for effective tracing of the contamination source.

Irrespective of how big or small brewery is, one need a system in place for process hygiene that includes checklists, standard operating procedures, and an audit.

Adherence to high hygiene standards pays dividends in the perceived and actual quality of the beer. Customer perception is a reflection of the brand, and people will think “If the brewery is clean, then the beer must be clean, too”. Cleanliness in the brewery leads to clean tasting beer.